Simplifying Global Equipment Designs by Utilizing Silicon Carbide

Article

Semiconductor fabrication and assembly sites are distributed globally and operate on a wide range of utility voltages. To serve the global market, OEMs that sell specialized equipment into these applications need to have multiple input voltage options on their equipment. That is why Astrodyne TDI (ATDI) selected Wolfspeed Silicon Carbide (SiC) MOSFETs for their new Kodiak power supply platform.

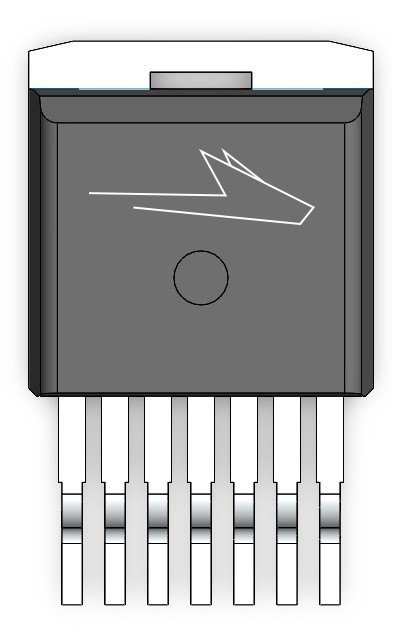

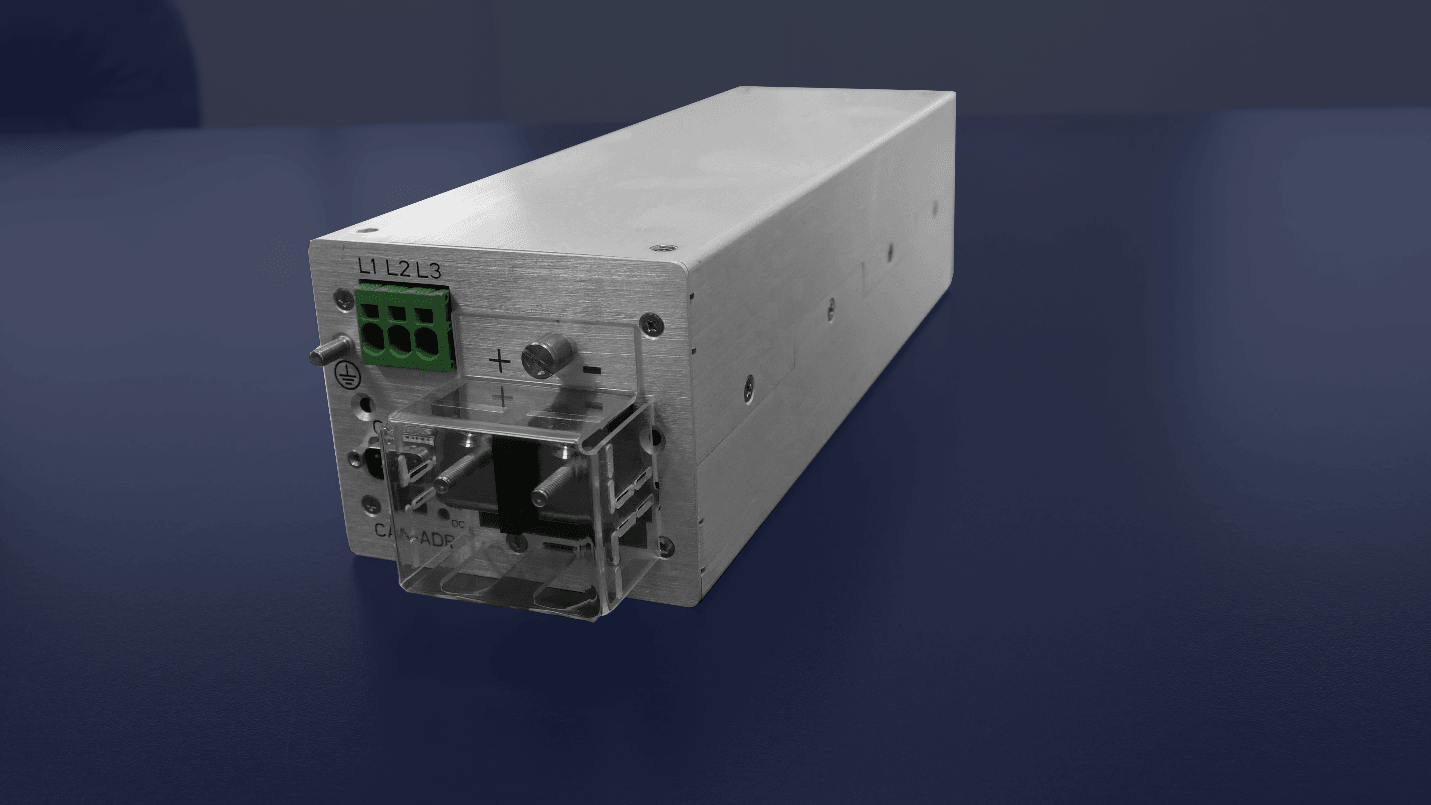

The Kodiak platform includes models for 208/230VAC and 400/480VAC input in a common package to eliminate the need for ATDI’s customers to redesign their systems to operate in different regions. This design commonality is made possible by Wolfspeed’s SiC MOSFETs in a TO-263-7 surface mount package with both 650V and 1200V families.

Next-generation semiconductor fabrication and assembly companies are seeking equipment commonality at sites in diverse locations to simplify operations and reduce time qualifying new equipment. This requires equipment that utilizes a single core design but with models that are capable of handling different utility voltages at diverse facilities while maintaining compliance with local and international safety and performance standards. Astrodyne TDI is leveraging SiC technology in collaboration with Wolfspeed to address these challenges faced by OEMs supporting next-gen fab/assembly customers. Their solutions provide power systems that use the same control and power topology across different utility voltage levels. Having a similar design for all voltage ranges makes it easier for customers to integrate these systems without changing their designs or qualifying different equipment at each manufacturing site with different utility voltages.

Flexibility brings powerful scalability

By utilizing a single form-factor and power topology, ATDI’s power supplies simplify the design and qualification process for their customers who integrate the power supply into process and test equipment. This also reduces the burden on the fab/assembly end-customers because they can expect the same performance from the equipment even if they have facilities at different locations with different utility voltages.

Ideally, next-gen fab/assembly sites want the option of a single yet flexible power platform for back-end and front-end processes at all locations and facilities. This is now possible by using 650V and 1200V SiC MOSFETs to enable one topology to work from 208 to 480VAC input with small design changes. SiC MOSFETs are the only technology that enables the active front-end and phase-shifted full-bridge topology at both 208/230V and 400/480V levels.

By using Wolfspeed SiC technology, ATDI’s Kodiak power supply platform can use the same power topology across different input voltages by simply switching out the SiC devices, magnetics and capacitors to operate at a different voltage level while maintaining the same capabilities within the same package. In addition, Wolfspeed’s broad portfolio of devices in both 650V and 1200V ratings allow for design optimization at each level. This level of commonality is not possible with silicon MOSFETs or GaN devices because of their limited voltage ratings, nor are silicon IGBTs a viable solution due to the much higher switching losses compared to SiC.

This flexibility allows customers to qualify and utilize a similar product in different facilities and locations with different input voltages. Development and qualification time is significantly reduced, and implementation is simplified. By using a consistent mechanical form factor, power topology, and interface that’s already been vetted, OEMs save design time, and end-users know they will get consistent performance at all their manufacturing sites.

Flexibility without distortion

Beyond the flexibility of ATDI’s single design using Wolfspeed SiC technology, there are other challenges faced by next-gen fab/assembly sites that are addressed by the Kodiak power supply platform.

A critical challenge for any manufacturing site is power-line distortion which is caused by all power supplies and loads. This distortion needs to be to be limited to acceptable levels to avoid problems with other equipment and to meet utility requirements. The Kodiak power supply platform keeps the total harmonic distortion (THD) to less than 5%, meeting or exceeding power quality requirements. The Kodiak power supply also maintains adherence to the SemiF47 and IEC 61000-4-11 standards to ensure stable operation in the presence of power-line fluctuations.

While low-THD power supplies are relatively common in 230VAC applications, ATDI’s Kodiak power supply is unique in fact that it incorporates this performance without requiring external filtering even at the 400/480VAC level. This is achieved by utilizing a true 3-phase power factor correction topology and proprietary control techniques. By keeping THD so low, customers can avoid having to add other filters at the system or facility level or troubleshooting potential interference issues between equipment.

A single design that empowers many products

By adopting Wolfspeed SiC technology, ATDI addresses the key challenges that OEMs face when designing equipment for the global market where utility voltages differ. End-customers including next-gen fab/assembly sites benefit from utilizing common equipment across different facilities and realizing the value of using SiC compared with silicon-based power supplies. The Kodiak power supply platform gives customers the ability to use the same control and power topology across different utility voltage levels, ensuring high performance regardless of the input voltage level. This common topology for all voltage ranges allows customers to integrate ATDI’s power supply into a wide range of products without changing their designs or qualifying different equipment to service facilities in different locations.

Learn more about Wolfspeed Silicon Carbide Power Products, ATDI Kodiak Power Supplies, and how Silicon Carbide Makes for Smarter Semi Fab/Process Power Supplies.