Enhancing System Durability with Advanced Packaging for Silicon Carbide (SiC)

Article

The electrification of various sectors is driving a growing demand for high-performance power devices across diverse applications and posing a new set of challenges for power design engineers. This demand is fueled by the adoption of Wide Bandgap (WBG) materials such as silicon carbide (SiC) and gallium nitride (GaN), which offer significant advantages in efficiency, power density, and reliability.

“Electrification of everything” also means that silicon carbide is used in more and more applications in a variety of working profiles, weather conditions and elevation levels. System requirements and performance expectations are different for an electric car driving in Florida than in Montreal. Demand for renewable energy is expected to soar by 2050. The operating conditions of wind turbines in the Baltic Sea are different from photovoltaic panels in Nevada desert. High-voltage applications are not created equally, yet high performance and reliability in challenging contexts - or true system durability - is becoming a common expectation. Reliability addresses consistency in test outcomes, while durability focuses on sustained operation in harsh environments over long lifetimes. Silicon carbide material’s intrinsic properties make it more durable than silicon at a material level. When we explore how power electronics can enable (or disable) an end-system’s ability to operate in a challenging environment, without excessive repair, then the true value of durability comes to light.

Full realization of the performance and durability benefits of SiC requires significant advancements in packaging technology. This white paper examines innovations in SiC power device packaging, highlighting their vital role in addressing the demands of modern power applications, particularly in electric vehicles (EVs) and fast charging infrastructure, industrial, and renewable energy farms. Learn more about Wolfspeed's power cycling and lifetime modeling approach.

Stringent performance expectations in automotive and industrial applications

The electric vehicle transition demands robust fast charging infrastructure, with systems ranging from 50kW to 1MW + . A typical 50kW charger performing 20 daily cycles accumulates over 70,000 cycles per decade, requiring exceptional power module durability under extensive temperature cycling from ambient to high junction temperatures.

Silicon carbide (SiC) technology surpasses traditional silicon IGBTs through superior efficiency, higher operational temperatures, extended lifetimes, and compact designs. SiC enables high-efficiency energy conversion in solar inverters and wind systems, handling 1.2kV to 3.3kV+ voltages while operating reliably above 150°C, reducing cooling requirements in harsh environments.

In industrial applications, SiC increases power density for motor drives, robotics, and automation systems. High switching frequencies enable compact component designs while wide bandgap properties minimize energy losses under demanding loads. Industrial environments require components that are resistant to mechanical stress, contamination, and extreme conditions.

However, SiC presents packaging challenges. Materials with higher Young's modulus create increased mechanical stress on bond wires during thermal cycling, potentially compromising electrical connections. Thermal expansion mismatches between components operating at elevated temperatures further amplify stress effects.

Advanced assembly techniques, specialized bonding materials, and enhanced thermal management systems are critical for mitigating these challenges. SiC must balance performance advantages with cost considerations, system compatibility, robust packaging, and adherence to safety standards. Despite challenges, SiC has emerged as a cornerstone technology for advancing clean energy systems and enhancing industrial efficiency.

Optimizing power packaging for SiC devices

As power density, efficiency, and reliability become more critical, Wolfspeed is introducing innovative approaches to enhance device performance and ensure durability under challenging conditions.

In scenarios involving frequent power and temperature cycling, material selection and connection methodologies play pivotal roles in maintaining reliability and performance. High switching speeds and exceptional thermal performance of SiC devices expose the limitations of conventional silicon-based power packaging.

Parasitic inductance in legacy designs leads to voltage overshoots, oscillations, and reduced reliability, necessitating compromises such as slower switching or higher-rated components, which add complexity and cost. Additionally, gate oscillations from inductive pathways can damage the sensitive gate oxide of SiC devices. To fully realize the benefits of SiC - such as higher efficiency and compactness - power packaging must be optimized for SiC to minimize inductance, optimize current paths, and enhance overall system performance and durability.

Advanced packaging solutions

Modern packaging solutions tailored to SiC technology address these challenges effectively. By reducing parasitic inductance in power, gate, and common-source loops, these solutions enhance efficiency, lower switching losses, and reduce voltage overshoots.

Wolfspeed employs a comprehensive approach to parasitic inductance minimization through advanced packaging and design methodologies. The implementation of Kelvin source connections provides critical isolation between gate drive circuitry; both magnetically to avoid transformer action from high di/dt power currents and capacitively through high dv/dt switching nodes. The result is substantially reducing gate loop inductance, faster reachable switching speeds, minimized crosstalk between power and gate loops, and mitigation of die-to-die oscillations during switching events. Strategic module layout optimization focuses on minimizing commutation loop areas through deliberate component placement and judicious application of parallel current paths. Advanced package architectures feature shortened current paths and symmetrical gate drive configurations that collectively reduce electromagnetic coupling effects. These design principles are further refined in Wolfspeed's Gen 4 MOSFET platform, which integrates enhanced durability and efficiency characteristics inherently minimizing parasitic effects. This allows designers to use lower-rated SiC devices, thereby reducing costs while maintaining performance.

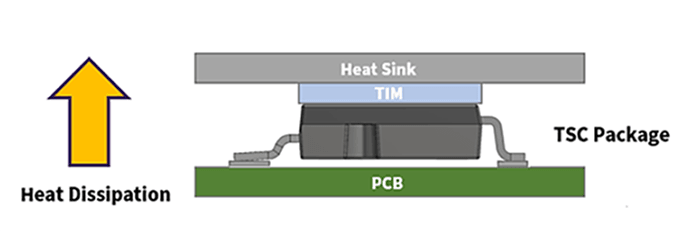

Most standard surface-mount power semiconductors dissipate heat through the bottom of the device that is soldered directly to the printed circuit board (PCB). The PCB is typically equipped with a heat sink or cooling plate underneath to manage the heat conducted through thermal vias in the PCB. This approach is widely used in various power electronics applications, especially when PCB-mounted heat sinks are not restricted by size or weight constraints.

In contrast, top-side-cooled (TSC) devices dissipate heat through the top of the package. These devices have their internal die and lead frame structure flipped, positioning it near the top surface to enable efficient heat transfer upward. TSC devices are particularly well-suited for high-performance applications like automotive and e-mobility systems where compact, high-power density designs necessitate advanced thermal management techniques. In such scenarios, TSC devices enhance cooling efficiency by reducing the total thermal resistance of the system allowing for greater power dissipation and improved thermal performance.

Wolfspeed’s “U2” top-side cooled packages include a standard 4.1 mm creepage distance across the creepage slot, or a 4.83 mm creepage distance around the creepage slot, representing a 10% improvement over comparable footprint compatible solutions in the market. Wolfspeed also designed the U2’s drain pins for improved system manufacturing reliability by reducing the likelihood of puncturing isolation barriers during system assembly.

TSC designs also free up the bottom side of the PCB for other uses since it no longer serves as the heat sink interface. This change (Figure 1) improves overall thermal impedance by removing the PCB from the thermal path. Additionally, TSC devices support automated assembly processes, boosting manufacturing efficiency and reducing costs.

Revolutionizing interconnections

Effective die connectivity is the cornerstone of robust power device performance. Traditional wire bonding - a staple for decades - is being replaced by advanced interconnection techniques that improve both thermal and mechanical properties. Reducing thermal resistance is essential for achieving smaller system size while maintaining high power density. Earlier designs relied on thick copper heat spreaders paired with high thermal conductivity insulating sheets, which, while effective, required meticulous assembly and had limitations in cooling performance.

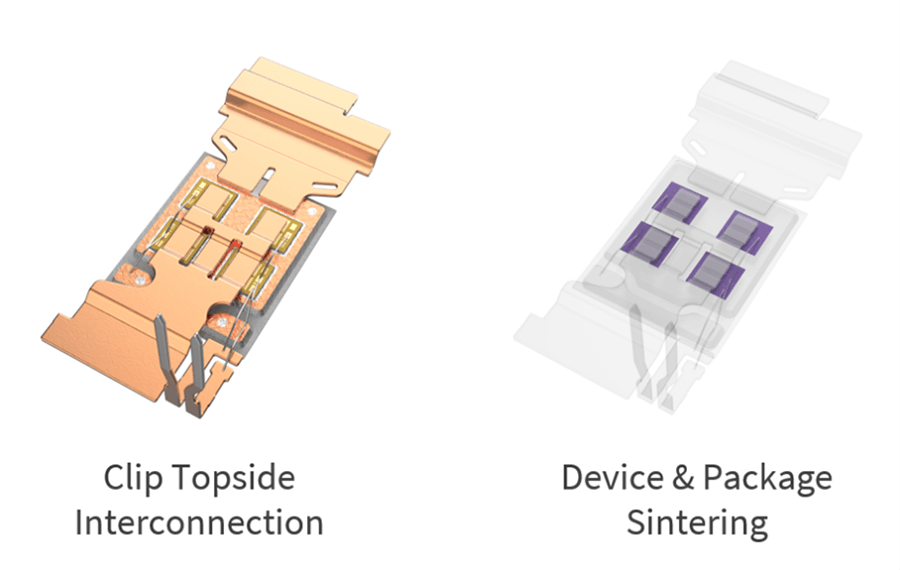

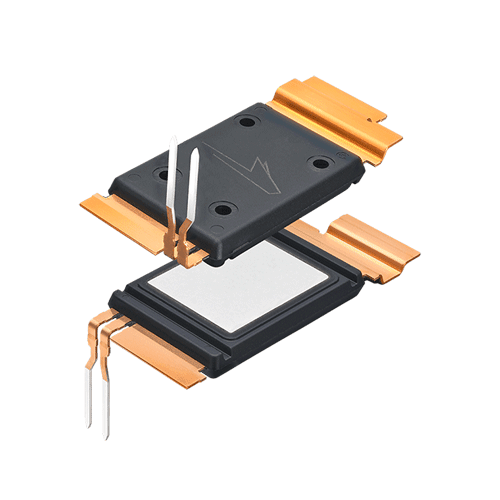

A noteworthy development is the adoption of top-side clip interconnections (see Figure 2), which offer lower resistance and inductance, enhanced thermal management, and superior mechanical reliability. Depending on the application, copper clips can be attached through soldering, laser welding, or sintering, providing versatility. Soldering large metal clips directly to the die enhances power flow within the module and strengthens connections.

In die-attach operations, silver sintering has emerged as a cutting-edge technique. This method forms a robust bond between the die and power substrate's materialization layer - using heat, pressure, and time. Applications requiring high power and thermal cycling durability benefit greatly from the mechanical bond strength provided by silver sintering, which also ensures excellent heat conductivity.

Innovations in cooling technologies

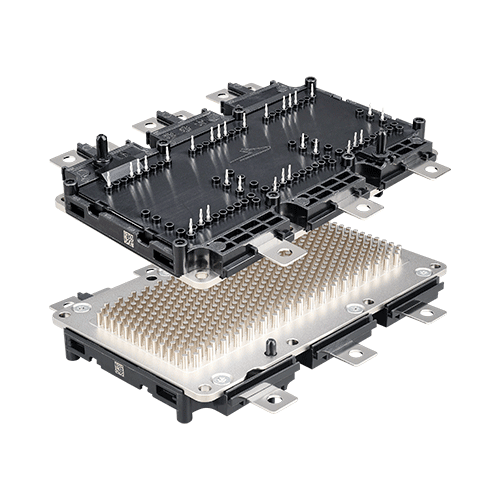

As power densities increase, effective thermal management becomes critical to maintaining performance and reliability. Direct cooling techniques are particularly transformative in automotive applications. For instance, pin-fin cooling designs integrate fins on the base plate of the module, which are submerged directly into the coolant within the inverter system. This approach efficiently dissipates heat from the die, ensuring that SiC devices, known for their exceptional performance at high temperatures, remain cool enough to sustain continuous power output.

The new family of automotive-qualified 6-pack power modules (YM4) represents an advanced packaging technology optimized for demanding automotive and e-mobility applications. These innovative modules integrate several advanced solutions to address the critical durability requirements of next-generation SiC applications where conventional packaging solutions fall short.

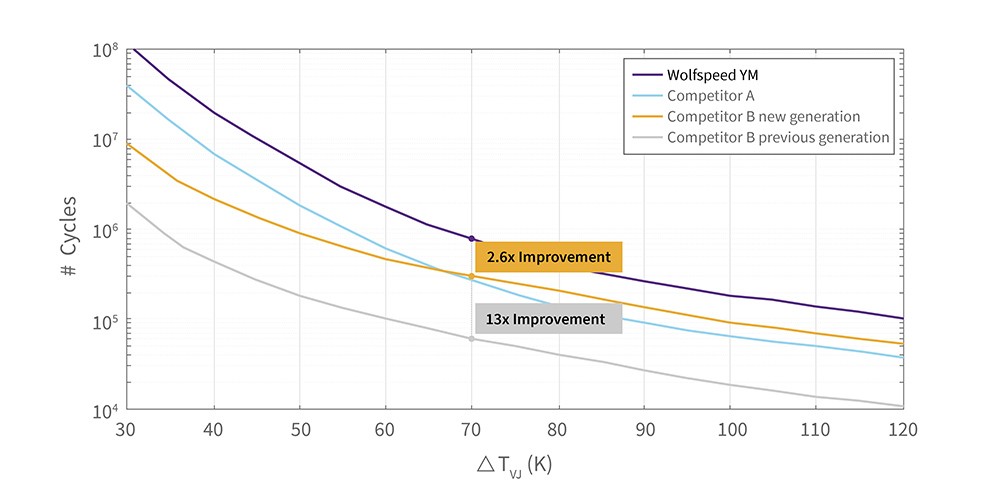

The YM4 modules feature sintered die attach technology for superior thermal conductivity and mechanical reliability, combined with advanced epoxy encapsulant materials that provide exceptional environmental protection and thermal stability. The copper clip interconnect system eliminates traditional bond wire limitations, enabling higher current density and improved thermal management. This comprehensive packaging approach delivers three times more power cycles than best-in-class competitor devices in the same footprint, ensuring extended operational lifetime under extreme thermal cycling conditions.

Enhancing Reliability

Reliability is a cornerstone of power device design, particularly in automotive applications where stringent qualification standards such as AEC-Q101 and AQG324 must be met. These standards require modules to undergo rigorous pre- and post-reliability testing, ensuring they can withstand harsh automotive environments.

One notable innovation is the transition from gel-based encapsulants to epoxy mold compounds. Unlike gels, which can absorb moisture and lead to arcing issues, epoxy resins offer superior resistance to moisture intrusion while enhancing structural integrity. This advancement strengthens the mechanical barrier around interconnections, improving the overall durability of the module.

Automotive-qualified single switch overmolded modules (TM4) showcase superior thermal engineering through innovative packaging technologies. By implementing copper clip bonding combined with silver-sintered packaging, these modules achieve up to 8% improvement in thermal performance while simultaneously enhancing power cycling capabilities.

Press-Fit Pin Technology and Low-Inductance Designs

Advances in press-fit pin technology are enabling higher current capacities for connections to printed circuit boards (PCBs). New designs are doubling the typical current-handling capacity of standard pins, supporting higher power densities in compact module configurations.

Low inductance is crucial for achieving clean and efficient switching. High inductance leads to large voltage swings and oscillations, which can reduce efficiency and stress components. By incorporating internal bus bars and clip attachments, advanced designs achieve inductance as low as 5 nH . This improvement minimizes oscillations, reduces switching losses, and enhances overall system efficiency.

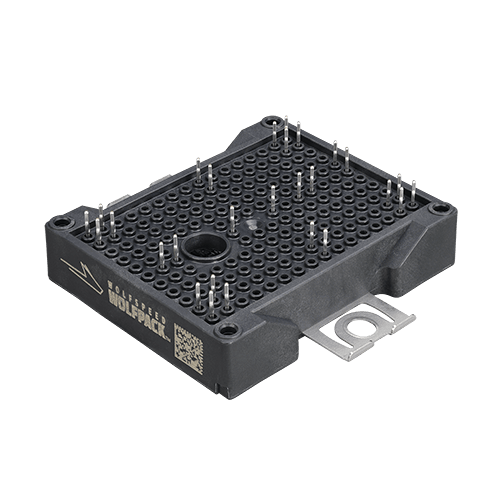

Wolfspeed's WolfPACK™ represents a significant advancement in power electronics packaging. Designed with flexibility in mind, WolfPACK modules (Figure 6) can be tailored to accommodate diverse power electronic topologies, ranging from half-bridge, full-bridge, t-style and 6-pack configurations, and can be scaled to meet varying power demands.

A cornerstone of WolfPACK's innovation lies in its utilization of Press-Fit technology. This innovative approach eliminates the need for traditional solder joints, resulting in several key advantages. By forgoing solder, thermal resistance is significantly reduced, enabling more efficient heat dissipation and consequently higher power densities. Moreover, the absence of solder mitigates the risk of solder fatigue, a common source of reliability issues in conventional power modules, leading to enhanced long-term durability.

Furthermore, WolfPACK modules are meticulously engineered with integrated thermal management solutions, such as a built-in Negative Temperature Coefficient (NTC) sensor Wolfspeed recognizes the critical importance of effective heat dissipation for optimal SiC device performance and has incorporated sophisticated cooling mechanisms into the module design. This ensures that the devices operate within safe temperature limits, maximizing their efficiency and lifespan.

Conclusion

The integration of advanced packaging solutions, innovative interconnection techniques, and effective thermal management strategies extends the capabilities of SiC power devices. These developments not only improve reliability and efficiency but also support higher power densities, paving the way for more compact, powerful, and energy-efficient systems in automotive, industrial, and renewable energy sectors.

To meet critical customer performance expectations and enable comprehensive electrification, Wolfspeed drives continuous innovation in both SiC die technology and advanced packaging solutions, maximizing silicon carbide's transformative potential across automotive, industrial, and energy applications.