Continue Reading Case Study

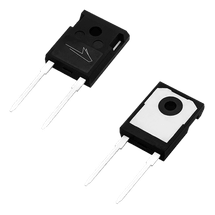

Bare Die Silicon Carbide Schottky Diodes

Wolfspeed has the broadest portfolio of Silicon Carbide (SiC) Schottky diodes, with more than 13+ trillion field hours, lowest FIT rate, and 35 years of experience in Silicon Carbide, combined with the fastest delivery times. Our diodes feature the MPS (Merged PiN Schottky) design which is more robust and reliable than standard Schottky barrier diodes. Pairing Wolfspeed Silicon Carbide diodes with Silicon Carbide MOSFETs creates a powerful combination of higher efficiency and reduced component pricing when purchased together.

Products

Bare Die Silicon Carbide Schottky Diodes

No filters selected, showing all 29 products

Bare Die Silicon Carbide Schottky Diodes - Filter By

Bare Die Silicon Carbide Schottky Diodes

Product SKU | Buy Online | Data Sheet | Status | Qualification | Blocking Voltage | Current Rating | Total Capacitive Charge (QC (typ)) | Tjmax | Generation |

|---|---|---|---|---|---|---|---|---|---|

Active | Industrial | 1200 V | 5 A | 38 nC | 175 °C | Gen 6 | |||

Active | Industrial | 1200 V | 10 A | 42 nC | 175 °C | Gen 6 | |||

Active | Industrial | 1200 V | 15 A | 90 nC | 175 °C | Gen 6 | |||

Active | Industrial | 1200 V | 20 A | 119 nC | 175 °C | Gen 6 | |||

Active | Industrial | 1200 V | 50 A | 279 nC | 175 °C | Gen 6 | |||

Active | Industrial | 1700 V | 5 A | 79 nC | 175 °C | Gen 6 | |||

Active | Industrial | 1700 V | 10 A | 126 nC | 175 °C | Gen 6 | |||

Active | Industrial | 1700 V | 25 A | 325 nC | 175 °C | Gen 6 | |||

Active | Industrial | 1700 V | 50 A | 479 nC | 175 °C | Gen 6 | |||

Last Time Buy | Industrial | 600 V | 2 A | 4.8 nC | 175 °C | Gen 3 | |||

Last Time Buy | Industrial | 600 V | 3 A | 6.7 nC | 175 °C | Gen 3 | |||

Last Time Buy | Industrial | 600 V | 4 A | 8.5 nC | 175 °C | Gen 3 | |||

Last Time Buy | Industrial | 600 V | 6 A | 15 nC | 175 °C | Gen 2 | |||

Last Time Buy | Industrial | 600 V | 8 A | 21 nC | 175 °C | Gen 2 | |||

Last Time Buy | Industrial | 600 V | 10 A | 24 nC | 175 °C | Gen 2 | |||

Last Time Buy | Industrial | 650 V | 4 A | 8.5 nC | 175 °C | Gen 3 | |||

Last Time Buy | Industrial | 650 V | 6 A | 15 nC | 175 °C | Gen 2 | |||

Last Time Buy | Industrial | 650 V | 8 A | 20 nC | 175 °C | Gen 2 | |||

Last Time Buy | Industrial | 650 V | 10 A | 24 nC | 175 °C | Gen 2 | |||

Last Time Buy | Industrial | 650 V | 12 A | 34 nC | 175 °C | Gen 2 | |||

Last Time Buy | Industrial | 650 V | 16 A | 44.5 nC | 175 °C | Gen 2 | |||

Last Time Buy | Industrial | 1200 V | 2 A | 11 nC | 175 °C | Gen 4 | |||

Last Time Buy | Industrial | 1200 V | 5 A | 27 nC | 175 °C | Gen 4 | |||

Last Time Buy | Industrial | 1200 V | 8 A | 37 nC | 175 °C | Gen 4 | |||

Last Time Buy | Automotive | 1200 V | 10 A | 56 nC | 175 °C | Gen 4 | |||

Last Time Buy | Industrial | 1200 V | 10 A | 52 nC | 175 °C | Gen 4 | |||

Last Time Buy | Industrial | 1200 V | 15 A | 77.5 nC | 175 °C | Gen 4 | |||

Last Time Buy | Automotive | 1200 V | 20 A | 99 nC | 175 °C | Gen 4 | |||

Last Time Buy | Industrial | 1200 V | 20 A | 99 nC | 175 °C | Gen 4 |

Explore The Options

Documents, Tools & Support

- Technical & Sales Documents

- Tools & Support

- Compliance

Documents

Document Type | Document Name | Last Updated |

|---|---|---|

| User Guide | 03/2023 | |

| Application Notes | 01/2024 | |

| Application Notes | 05/2023 | |

| Application Notes | 09/2022 | |

| Application Notes | 02/2022 | |

| Application Notes | 09/2015 | |

| Sales Terms | 12/2021 |

Knowledge Center

Beat the Heat This Summer with Wolfspeed SiC in Residential & Commercial Air Conditioners and Heat Pumps

Silicon carbide is revolutionizing the heat pump and air conditioning industry by delivering unprecedented efficiency, enhanced durability, and superior performance in the most challenging of environments.

Continue Reading Technical Articles

Practical Tools for Designing with Silicon Carbide in Industrial Motor Drives

Simplify, accelerate and de-risk the design process when designing industrial motor drives with silicon carbide and easily access IE4 and IE5 efficiency standards.

Continue Reading Blog