SiC Materials

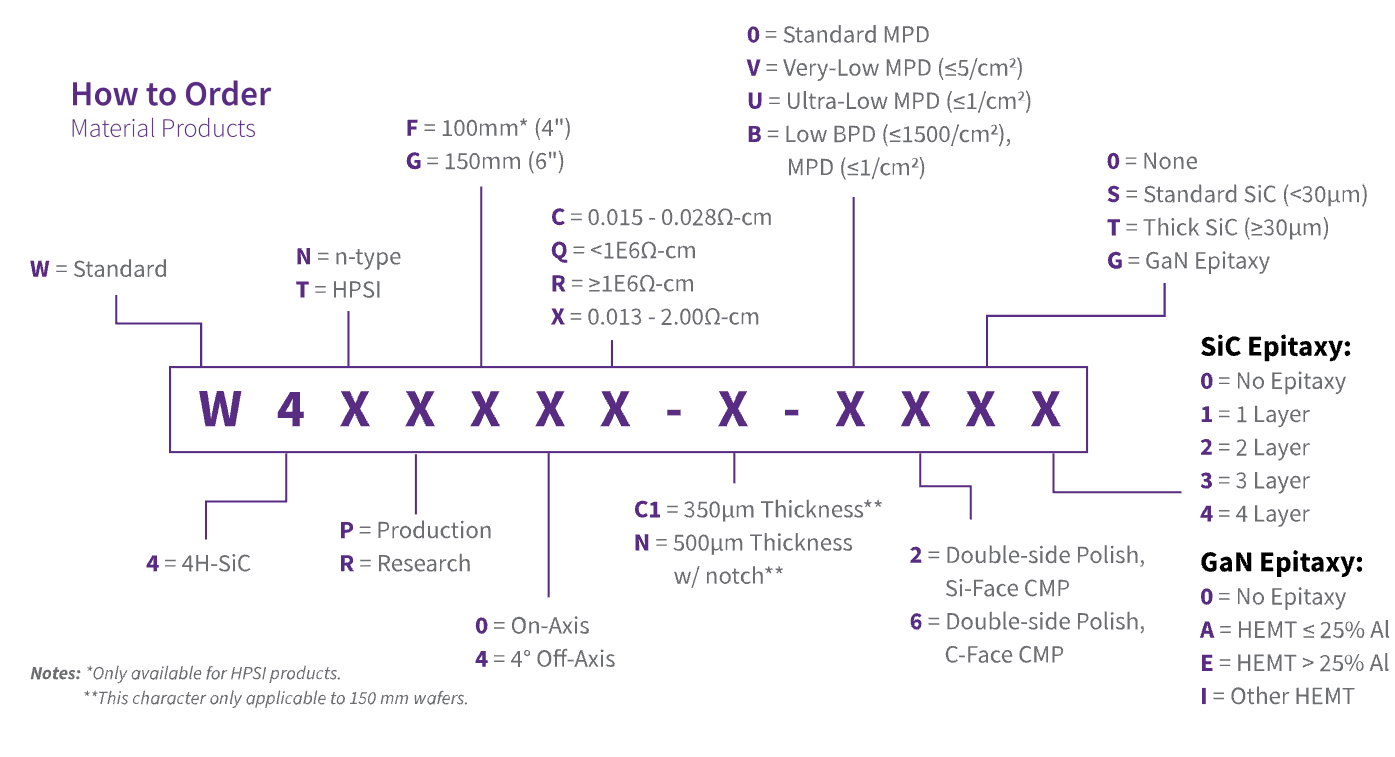

Materials Products

Industry-Leading Portfolio, Innovation and Scale

With more than 30 years of SiC development and manufacturing experience, Wolfspeed produces the industry’s broadest range of SiC materials. Offering n-type conductive SiC products and a variety of SiC epitaxy options, Wolfspeed delivers the quality and quantity necessary to support the rapidly expanding demand for high-efficiency, SiC power semiconductors.

When you partner with Wolfspeed, you get the best and most innovative materials.

Products

Physical Properties

Polytype | Single-Crystal 4H |

Supported diameters | 150mm & 200mm |

Crystal structure | Hexagonal |

Bandgap | 3.26 eV |

Thermal conductivity (n-type; 0.020 Ω*cm) | a~4.2 W/cm • K @ 298 K c~3.7 W/cm • K @ 298 K |

Thermal conductivity (HPSI) | a~4.9 W/cm • K @ 298 K c~3.9 W/cm • K @ 298 K |

Lattice parameters | a=3.073 Å c=10.053 Å |

Mohs hardness | 9 |

Dimensional Properties, Terminology, & Methods

Diameter | The linear dimension across the surface of the wafer. Measurement is performed using an automated micrometer, traceable to the ANSI standard, providing the average value for each individual wafer. |

Thickness, Center Point | Measured with ANSI-certified non-contact tools at the center of each individual wafer. |

Surface Orientation | Denotes the orientation of the surface of a wafer with respect to a crystallographic plane within the lattice structure. In wafers cut intentionally “off orientation,” the direction of cut is parallel to the primary flat, away from the secondary flat. Measured with x-ray goniometer on a sample of one wafer per boule in the center of the wafer. |

Orthogonal Misorientation | In wafers intentionally cut “off orientation,” the angle between the projection of the surface normal onto a (0001) plane and the nearest [1120] direction. |