The Power to Make It Real™

At Wolfspeed, we are the creators of the next-generation semiconductor technology that powers the world’s most disruptive innovations. In other words, it’s our job to make humankind’s greatest ambitions – real.

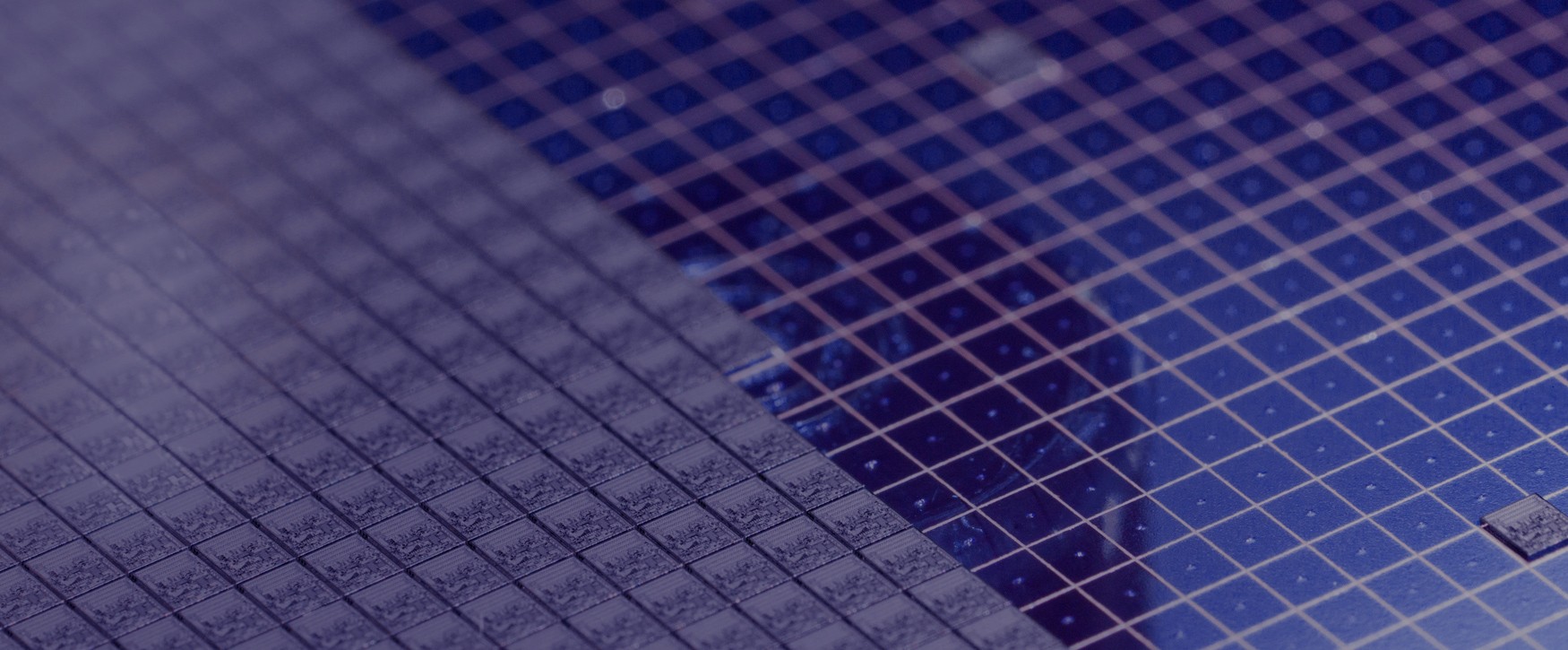

For us, making it real means making it the Wolfspeed way. We deliver unparalleled reliability on a massive scale from the first U.S.-based silicon carbide corridor with end-to-end substrate and power device fabrication to fulfill the world’s growing demand.

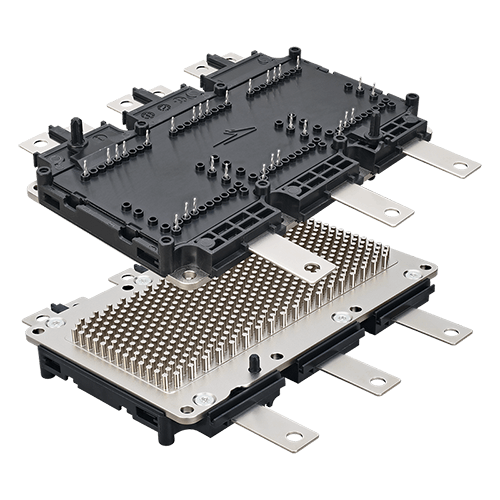

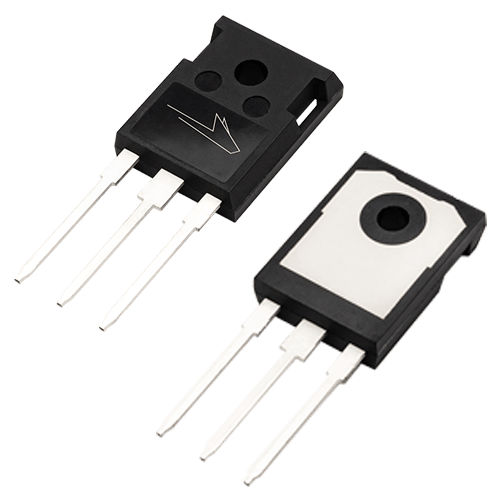

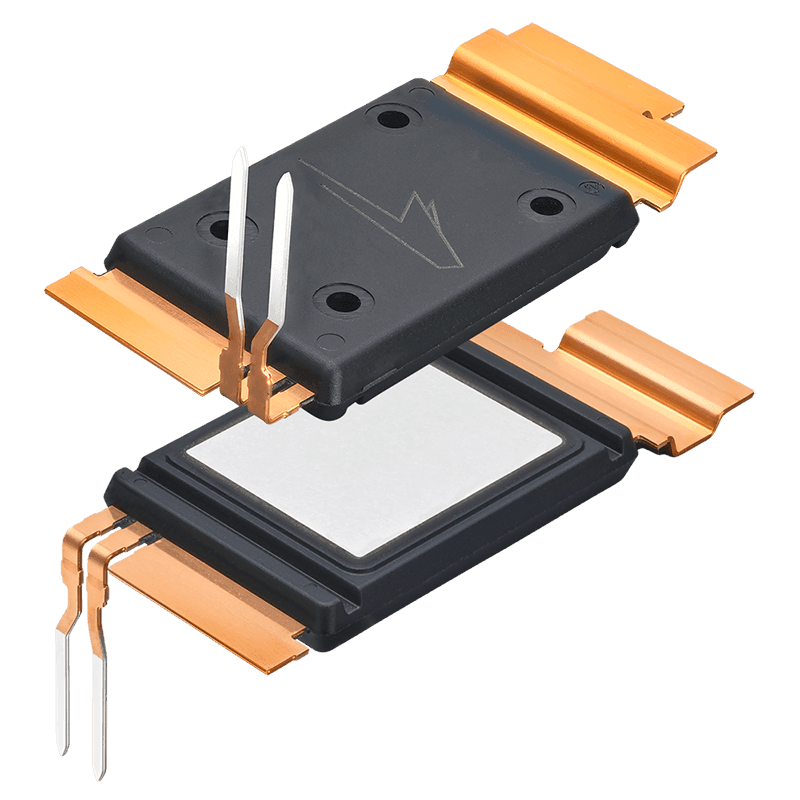

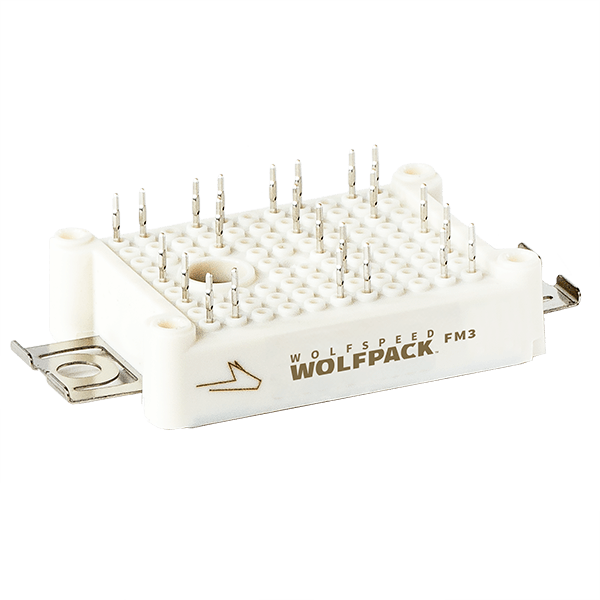

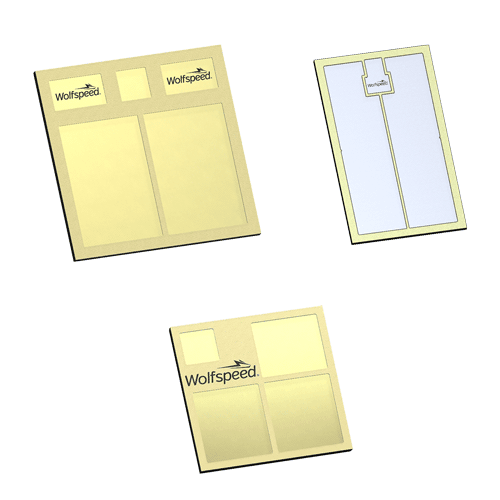

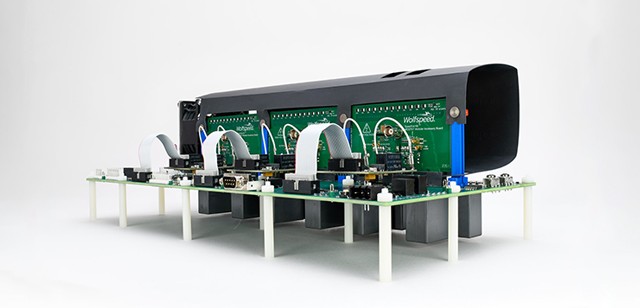

Latest Product Releases

Our technology commitment

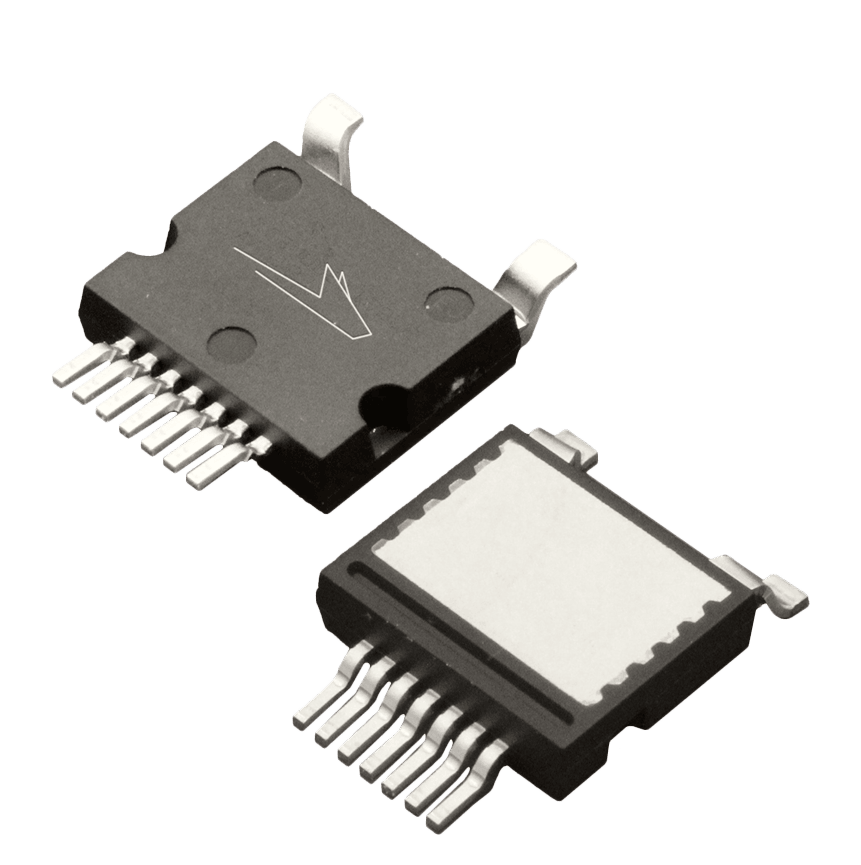

Designed to comprehensively improve system efficiency

We empower our customers to more effectively create, convert and store energy with technology providing higher ampacity while minimizing conduction and switching losses.

Designed to reduce system cost and development time

We equip our customers to pivot to new system architectures to minimize their maintenance costs and production time with clean switching and high-performance devices.