Designing with Top Side Cooled (TSC) Silicon Carbide Power Devices

Article

Designers of high-voltage systems are turning to silicon carbide for its intrinsic temperature and switching performance behaviors across a growing list of power electronics applications. Engineers often face multi-faceted system design requirements, including the need for multi-sourced packages capable of supporting tight power density constraints with limited thermal dissipation design possibilities.

Wolfspeed is now expanding system design options by commercially releasing a well-known top-side cooled package to both automotive and industrial markets. As a drop-in replacement for MOSFETs produced by other suppliers, the U2 package enables procurement flexibility for established designs with improved package creepage to support designs from 650 V – 1200 V.

System-level benefits of top-side cooled packages

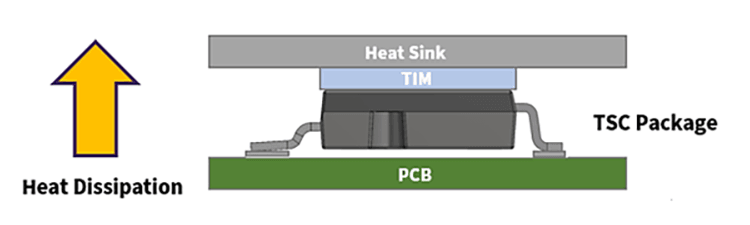

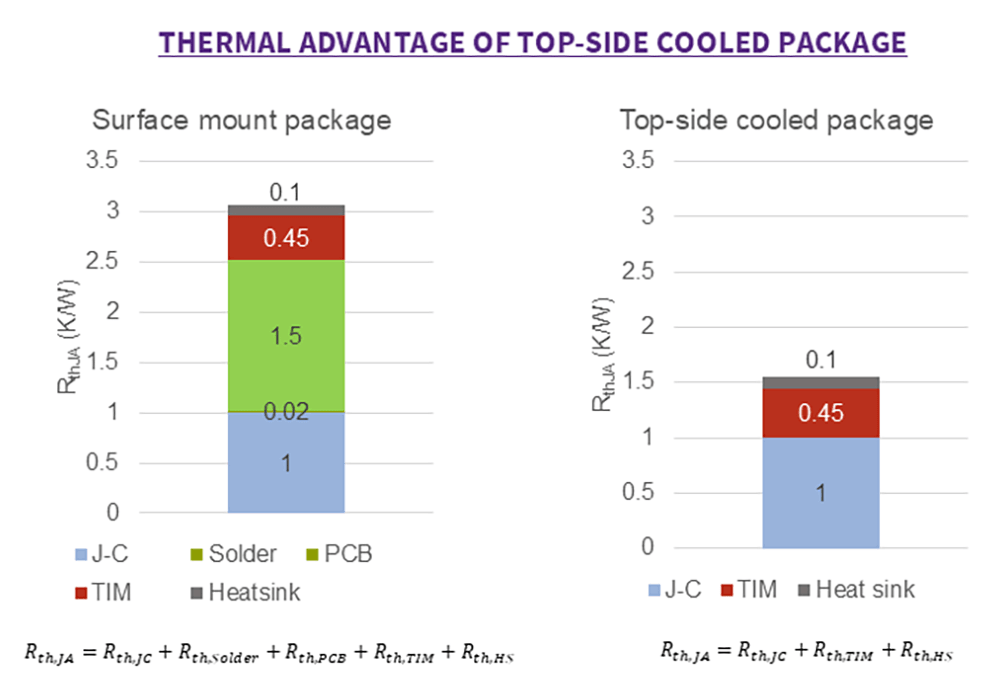

Most standard surface mount discrete power semiconductors remove heat through the bottom of the device by making direct contact with the power circuit board (PCB), which utilizes a heat sink or cooling plate attached underneath. This method is common across many different power electronics applications, particularly when size and weight requirements do not limit PCB mounting and heat sinks.

Top side cooled (TSC) devices, on the other hand, dissipate heat through the top side of the package. Inside TSC packages, the die orientation against the drain tab allows heat to flow directly to the top surface. Top-side cooled packages address cooling requirements by enabling maximum power dissipation and optimizing thermal performance.

TSC designs also allow for dual-side usage of the PCB since the bottom board surface is no longer needed for the heatsink interface. Table 1 below shows a comparison of the thermal resistance (Rθ) network of a standard bottom-side cooled SMD package versus a Wolfspeed top-side cooled package. Removing the heatsink from the thermal path not only creates an improved overall system thermal impedance, it also allows for automated assembly, which can increase manufacturing throughput for a more efficient and cost-effective solution.

Operate confidently in challenging environments

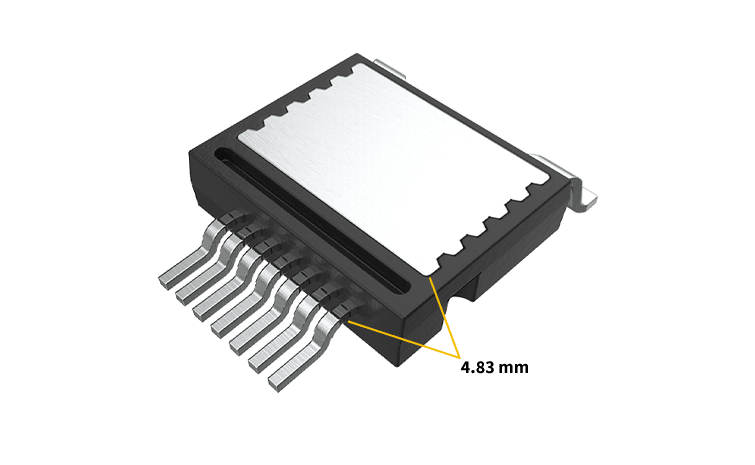

As 800-V vehicle architectures proliferate the BEV landscape, system designers must ensure that high voltage system safety specifications evolve from original 400 V based designs. One way Wolfspeed is helping system designers confront this challenge is by expanding the creepage distance of the package to prevent damaging electrical breakdown events. Wolfspeed’s “U2” top-side cooled packages include a standard 4.1 mm creepage distance across the creepage slot, or a 4.83 mm creepage distance around the creepage slot, representing a 10% improvement over comparable footprint compatible solutions in the market. Wolfspeed also designed the U2’s drain pins for improved system manufacturing reliability by reducing the likelihood of puncturing isolation barriers during system assembly.

In addition to a more reliable package design, automotive design engineers can now sample top-side cooled devices that include Wolfspeed Gen 4 platform die technology. These MOSFETs offer best-in-class switching performance across the operating temperature range, with broad Vgs compatibility including +18V and -0V operation. Gen 4 also a soft body diode, resulting in lower Vds peaks during turn off – this allows designed to push Wolfspeed’s Gen4 MOSFET harder than competitive devices without FIT rate concerns. Devices like the new 1200-V Gen 4 25 mΩ MOSFET have completed AEC-Q101 qualification, making this industry leading performance readily available for testing in customer’s designs.

A portfolio that scales with your design requirements

With options ranging from 650 V – 1200 V, Wolfspeed’s surface mount TSC products significantly increase system level power density and efficiency, while improving thermal management and board layout flexibility. AEC Q101 qualified 1200-V devices are available across the 16 – 160 mΩ range, and industrial grade devices are available to sample as pre-production or production-ready.

Two simple ways to get started

- Copy and paste a 13 kW system: Wolfspeed’s 13 kW automotive motor drive reference design demonstrates the benefits of U2 devices for battery thermal management (HVAC) systems. Optimizing the efficiency and operating temperature range of the HVAC system via a SiC based system enables OEMs to bring fast charging to the driver in under 15 minutes, while also extending the driving range per charge for the lifetime of the car.

- Simplify your assembly: Our applications experts explain TSC SMD assembly and mounting considerations, as well as thermal measurement analysis. This material also includes extensive thermal interface material (TIM) studies on TSC packages with system-level testing results.