Sun to Wheels: Powering a Renewable Future with Silicon Carbide

Article

As the world advances toward a sustainable, greener future, many countries are powering down fossil-fuel energy generation in favor of renewables. The global weighted-average cost of electricity from new utility-scale solar photovoltaic (PV) projects fell by 85% between 2010 and 2020, onshore wind by 56%, and offshore wind by 48%. Renewables have thus become the typical route for energy capacity addition in nearly all countries and the Compound Annual Growth Rate (CAGR) of cumulative PV installations, including off-grid, reached 34% between 2010 and 2020.1

This growth is set to continue with the added thrust toward increasing energy efficiency. An International Renewable Energy Agency (IRENA) report asserts that limiting global warming to 1.5°C would require cutting 36.9 Gt of annual carbon dioxide emissions and has recommended a target of an additional 444 GW/year of solar PV and 248 GW/year of wind energy until the year 2050. IRENA estimates that significant increases in renewable energy and energy efficiency can each contribute no less than 25% toward achieving the targeted emissions reduction, while another 20% can be reached through electrification of such applications as transport.2

While research in new wind turbine designs and perovskite-based solar cells is pushing the limits of energy conversion efficiency, the power semiconductor chain between the generation to application of renewable energy need no longer be the weak link from the sun to the wheels. There are immense size, weight, power, and cost (SWaP-C) benefits available today from simply swapping out legacy semiconductor technology for Silicon Carbide in energy connection, distribution, and storage systems

High efficiency in power electronics chain

For both 5-15 kW residential single-phase and 30-100 kW commercial three-phase architectures, arrays of solar panels are used to increase the voltage and reduce I2R losses in connections and cables. The PV array voltage is typically boosted to a regulated DC that charges an energy storage system (ESS) that helps tide over the power fluctuations typical of solar energy generation. Regulated DC is supplied to an inverter for DC-AC conversion, while a Maximum Power Point Tracking (MPPT) controller optimizes the load on the panels for the highest energy efficiency.

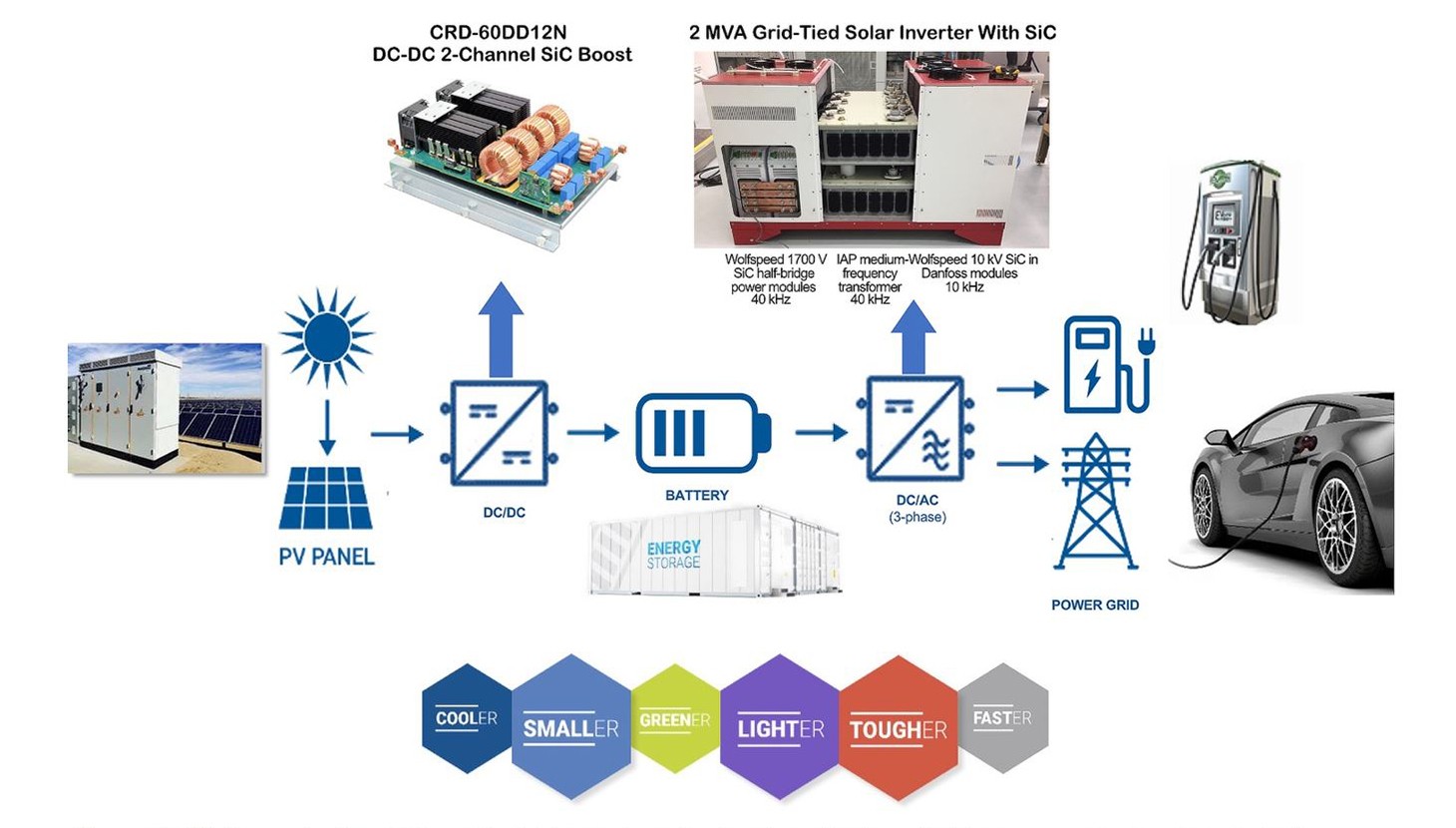

Wolfspeed offers Silicon Carbide devices that suit each stage in this power electronics chain and at the power levels needed by applications ranging from residential to light commercial to utility-scale. The company’s technology helps designers achieve higher system-level efficiency and power density with lower system cost — all main driving factors in the renewable energy market (Figure 1).

DC-DC Boost: The DC-DC section is used to boost the variable PV panel voltages. By replacing Silicon diodes and MOSFETs in this section for string type inverters with Wolfspeed’s Silicon Carbide modules, designers can reduce system size by 70% and increase system efficiency by 1% while lowering overall cost by 30%. This is the direct result of the ability to use higher switching frequencies, which reduce inductor, capacitor, filter and transformer sizes, costs, and packaging.

Energy Storage Systems: The ESS application offers tremendous opportunity for Silicon Carbide implementation from residential through industrial applications by fulfilling system requirement gaps left by Silicon in DC-DC boost/MPPT, bidirectional active front ends (AFEs), and DC battery chargers.

Wolfspeed tests with their Silicon Carbide solutions have shown nearly 3% increase in system efficiency, up to 50% higher power density, and significant reductions in passive component volume and passive BOM costs.

Mid- to high-voltage (MV/HV) Silicon Carbide MOSFET modules from 3.3 kV to 20+ kV open up several existing and emerging application spaces, including grid-tied inverters, super chargers, and traction.

Grid-tied PV Inverters: Enabled by MV/HV SiC devices, these inverters can connect solar farms directly to the grid thereby eliminating heavy, expensive, and lossy transformers from the power electronics chain. This lowers installation, operating, and siting costs of the PV power system.

For instance, such a 2 MVA grid tied inverter system would comprise the Wolfspeed 1700 V SiC half-bridge modules operating at 40 kHz, a smaller medium-frequency transformer at 40 kHz, and Wolfspeed 10 kV SiC modules at 10 kHz. It would weigh less than 1,000 lbs, excluding the transformer and achieve over 98% CEC efficiency.

DC Fast Charging: Traditional fast chargers typically use low-frequency transformers that add several thousand pounds to the overall system weight. This type of 500 kVA system would be a 5,190 liter (l), 3,537 kg charger with >28 kW power losses.

A modern 500 kVA fast charger based on Wolfspeed’s 6.5 kV SiC and a >20 kHz solid-state transformer (SST) is a ≤1,298 l, ≤530 kg system with ≤11.25 kW power losses. The Silicon Carbide-based DC fast charger can therefore achieve full-charge in less than 4 minutes, with a system that is >75% smaller and >85% lighter and has >60% lower losses as well as >40% lower costs.

Traction & Mobility: MV/HV SiC modules can decrease annual fuel consumption of transport by 1-4% and, in drive systems of heavy equipment, result in substantial savings on drive systems, cooling, and wiring.

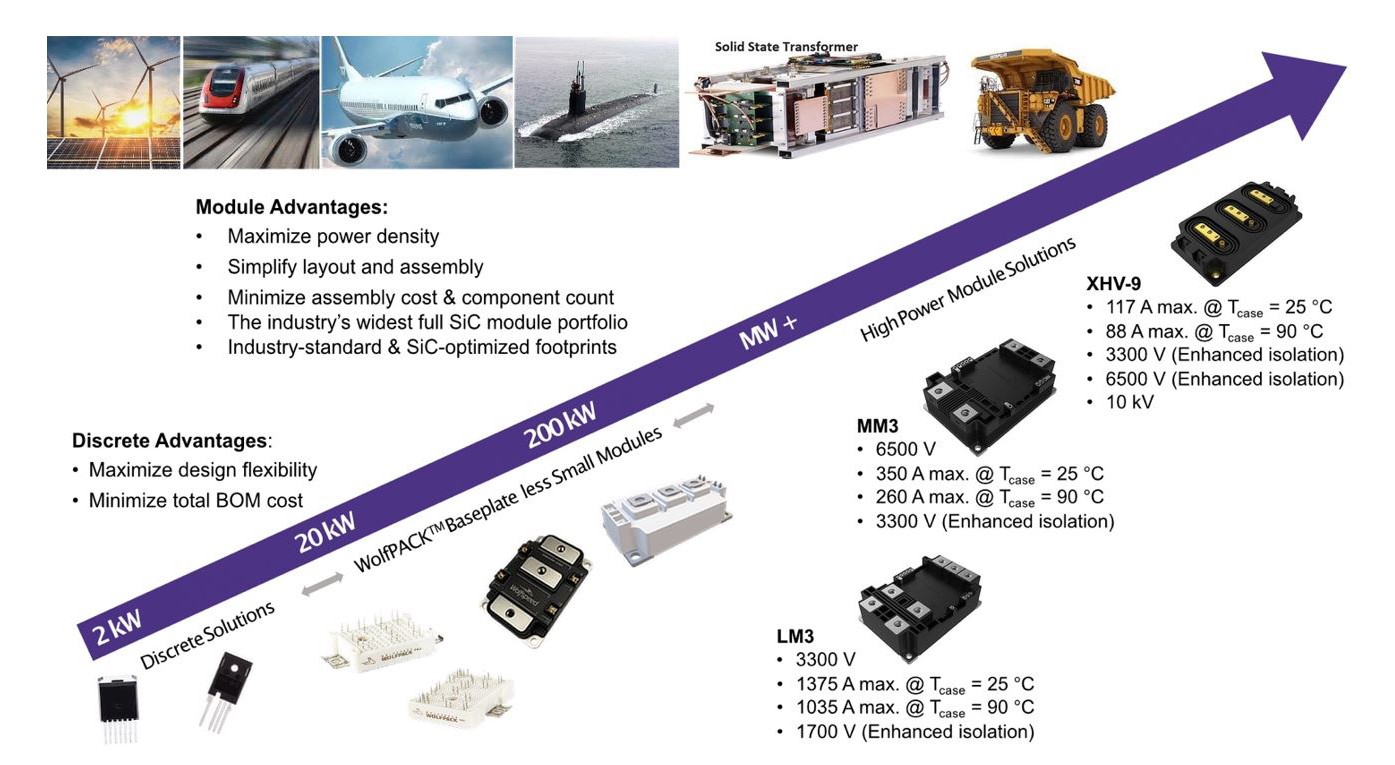

Ratings to meet wide application range

Wolfspeed offers Silicon Carbide discrete devices and modules that cover the industry’s widest application power scale (Figure 2). The company’s MV/HV solutions, rated from 3.3 kV LM3 modules to 6.5 kV MM3 and 10 kV XHV-9, address a broad range of voltage, current, and isolation requirements from the applications discussed above.

As a vertically integrated Silicon Carbide supplier with the largest market share and growing, Wolfspeed has over 30 years of experience, millions of MOSFETs and diodes in the field operating for trillions of hours.

To ask their experts about the benefits of Silicon Carbide technology and the devices that best suit your application, contact Wolfspeed here.

Article original source: Power Electric News

References

- Fraunhofer-Institut für Solare Energiesysteme, Photovoltaics Report, February 24, 2022 (https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/Photovoltaics-Report.pdf)

- IRENA, World Energy Transitions Outlook 2022, ISBN: 978-92-9260-429-5 (https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2022/Mar/IRENA_WETO_Summary_2022.pdf)