Wolfspeed powers Telcodium’s lightest 5kW Portable Power Station

Article

What comes to mind when you think of a ‘Portable Power Station’? A bulky and heavy machine that is loud, yet underpowered. A machine that frustrates customers.

Customers have had to use internal combustion engine (ICE) generators that are typically loud, large and heavy, and cannot be used indoor. Contrast this with electric systems that are typically smaller and lighter, addressing the portability issue, and also meet power requirements. This is where Telcodium started their journey to enable an all-electric lightweight solution that meets all of the customer requirements.

Telcodium, a designer and manufacturer of efficient power systems is an expert in this field. The company utilizes new hardware technology, wide bandgap semiconductors, and software-based control to focus on smaller, cooler, and smarter power products.

Telcodium knows this innovation-centered approach to power system design can open up new opportunities in a wide range of electrical products and markets. It therefore partnered with Wolfspeed to access the best available semiconductor technology. Wolfspeed, the leader in Wide Band Gap (WBG) technology, is the supplier of choice for state-of-the-art components that provide increased efficiency, higher switching frequency, reduced system size and weight.

Portable power stations are essentially used for providing back up power for emergency use and are gaining popularity in recreational uses. In addition, their use can be expanded to professional and industrial use, such as air compressors that power nailers, sprayers, and other pneumatic tools like portable electric welding equipment, metal chop saws, miter saws, circular saws, as well as grinders. This requires high continuous power and instant peak power at startup time.

WBG materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) are best suited to the high-power-density, small-size, and efficiency requirements that Telcodium needed to meet. Moreover, SiC and GaN devices have lower ON-resistances, conduction losses and reverse-recovery currents, significantly reducing switching losses while allowing operation at frequencies much higher than those possible with Silicon (Si). This reduces the size and weight of capacitors, inductors and transformers needed in power.

Telcodium targeted on an ambitious 5 kW goal for this application and completed the initial design using a familiar technology, GaN. Implemented as a 2-level DC-AC converter, also called an inverter, the use of GaN allowed for a highly portable design. However, the company soon realized GaN technology had limitations.

High continuous and peak power challenge

Engineers designing the new inverter had banked on the fact that while GaN has lower thermal conductivity at 1.3 W/cmK than Si’s 1.5 W/cmK, its much higher efficiency at similar voltages means it would run cooler than Si.

However, the design was dissipating considerable power during the high peak-power conditions that caused the GaN devices to overheat and fail.

The high peak-power conditions are frequently experienced in the target applications with many of the tools requiring high torque, and therefore high current draw, for a “hard start.”

Since any portable inverter supplying industrial tools is expected to handle peak power demands as smoothly as a direct plug-in AC connection, Telcodium needed another semiconductor technology solution and turned to Wolfspeed, a company with long experience in SiC, which with a higher thermal conductivity of 5W/cmK can dissipate heat nearly four times as rapidly as GaN.

Why Wolfspeed?

Wolfspeed is the largest vertically integrated supplier, offering SiC bare die, discrete components as well as modules, along with evaluation tools, gate drivers, reference designs, and free online simulation.

No company has over 30 years of experience and expertise with SiC as does Wolfspeed. SiC has powered the company’s MOSFETs, Schottky diodes, and power modules past six trillion hours of 650 V – 1700 V end-customer usage worldwide.

Vendor-selection was made even easier for Telcodium since Wolfspeed’s SiC MOSFETs offer leading-edge performance. For instance, Wolfspeed technology ensures the lowest and most stable RDS(ON) in the industry across a wide temperature range (figure 1).

Moreover, Wolfspeed’s ecosystem of support includes design consultation that Telcodium required, as well as reference designs and the powerful online SpeedFit™ 2.0 design simulator that allows quick calculation of power losses and estimation of junction temperature for most common topologies.

SiC MOSFET meets requirements

Wolfspeed engineers worked with Telcodium to identify a suitable SiC MOSFET – the C3M0015065K – to meet the requirements of the application. It is part of Wolfspeed’s 650 V MOSFET family that uses Wolfspeed’s industry-leading, third generation C3M™ MOSFET technology to achieve up to 20 percent lower switching losses than competing SiC parts and provides the lowest on-state resistances (RDS(ON)) for higher efficiency and power-dense solutions.

Compared to Si, the C3M0015065K MOSFETs deliver 75 percent lower switching losses and, due to its low 15mΩ RDS(ON), a 50 percent decrease in conduction losses. This results in a potential for 300 percent increase in power density.

And compared to SiC parts from other vendors, the 650V MOSFET has lower switching and conduction losses (figure 2), lower ON-resistance increase over operating temperature, lower output capacitance as well as higher switching frequency capability, while being easier to drive.

Wolfspeed ran simulations for the thermal characteristics of the SiC MOSFETs at Telcodium’s various operating points and demonstrated that replacing the GaN devices with C3M0015065K parts could help keep them within their rated temperatures and avoid damage.

Telcodium integrated Wolfspeed’s simulation data into a novel model-based software scheme in which the current through the converter is monitored on a per-cycle basis and the switching is stopped above a certain threshold.

The company was not able to achieve its design intent, in addition to reduce cost by eliminating the need for expensive and unreliable liquid cooling.

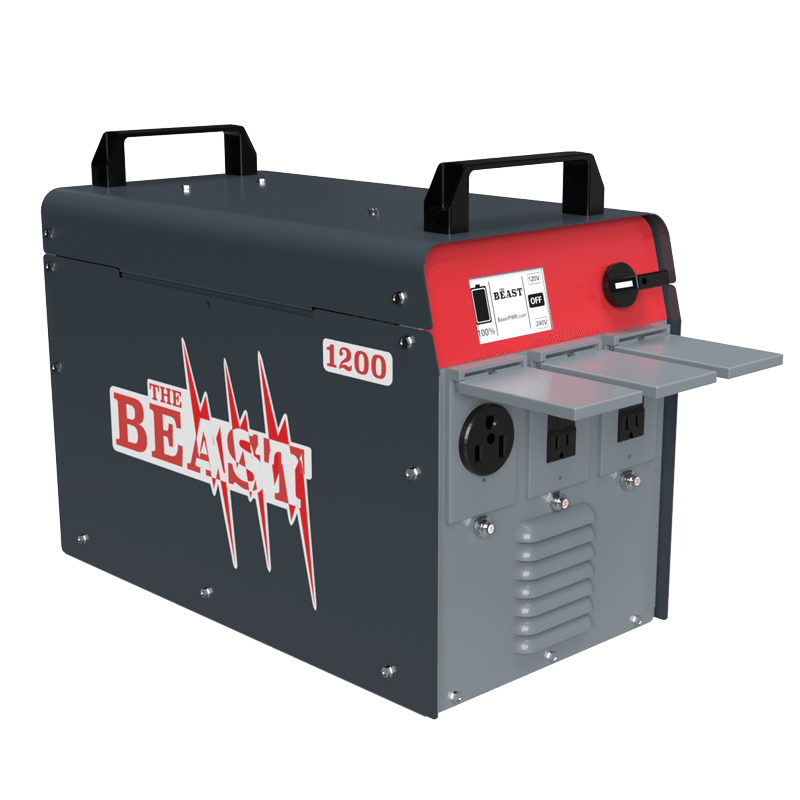

“The Beast,” as Telcodium calls it internally, runs with natural convection cooling up to 3 kW, providing a significant benefit for construction sites where forced air cooling is often not suitable.

The issue of fast startup

Telcodium’s market has had many challenges and has evolved the product by listening to customer requirements. Highly efficient, light, portable models use high switching frequency but must use “soft start” techniques that do not suit tools needing high starting torque. On the other hand, models with very high peak power ratings allowing fast startup are generally low-switching-speed transformer-based equipment which are neither portable nor as efficient as the high-frequency alternatives.

While Wolfspeed’s components helped solve the high peak current challenge with the C3M0015065K MOSFETs, Telcodium further optimized the overall system with the use of software-based techniques to safely achieve short startup times for various loads.

Building The Beast light

The key to portability is to lower the system weight and size. In an inverter, significant contributors to both these things are the cooling system used to dissipate system heat and the inductors used to filter output waveforms.

The Wolfspeed C3M0015065K SiC MOSFETs addressed this challenge as well. Unlike Si-based devices in which the body diode significantly limits switching performance, the C3M0015065K has a low reverse recovery charge and recovery time of 510 nC and 22 ns, respectively, at VGS = -4 V, ISD = 55.8 A, VR = 400 V dif/dt = 4000 A/μs. It can therefore operate at up to about 1,000X higher switching frequencies than Si devices, allowing Telcodium designers to reduce the size of the magnetics (figure 3).

With the high thermal conductivity previously mentioned as well as the high temperature operation (TJ = 175°C) possible with the SiC MOSFETs, Telcodium was able to reduce size and weight of the cooling system.

The result is that Telcodium’s inverter can now replace a 50 lb (22.7 kg) inverter that uses older technology with its new >10.5 lb (4.8 kg) solution (Reference Design part # TD-70-120VDC-120VAC-5kW) in a package that is nearly a third the size.

Scalable performance from Telcodium, Wolfspeed

When Telcodium decided to enhance the design specifications, the company chose Wolfspeed for its broad range of products, depth of expertise, and outstanding support – all key considerations when designing with leading-edge materials and technologies.

Telcodium used Wolfspeed parts and expertise to increase the power output, address the peak power challenge, and reach higher switching frequencies in a light, small form factor and offer:

- 5 kW sustained

- 120 or 240 VAC outputs

- 20 W/in3 (highest density)

- 2” x 12.5” x 10” results in a 250 cubic inches volume

- >10.5 lbs (4.8 kg) system Reference Design part # TD-70-120VDC-120VAC-5kW) weight

The 5-KW portable power station hardware is scalable to address new applications, including truck beds and RVs, and offers ODMs a quick time to market through hardware and software licensing.

Download the C3M0015065K datasheet or the TD-70-120VDC-120VAC-5KW spec sheet or ask a Wolfspeed SiC expert to help you with your power design challenge.

If your requirement is for a private labelled product, an ODM solution, or a licensing agreement, please visit Telcodium.com