Wolfspeed XM3 Power Module Family

Article

Wolfspeed's XM3 power module platform maximizes the benefits of silicon carbide, while keeping the module and system design robust, simple, and cost effective.

Package Benefits

- High Power Density Footprint

- High Temperature (175 °C) Operation

- Low Inductance (6.7 nH) Design

- Implements Third Generation SiC MOSFET Technology

Technical Features

- Terminal Layout Simplifies Bus Bar Design

- Integrated Temperature Sensing

- Dedicated Drain-Kelvin Pin

- Silicon Nitride Insulator and Copper Baseplate

Applications

- Motor & Traction Drives

- Uninterruptible Power Systems (UPS)

- EV Chargers

In order to reach high switching speeds with low switching losses, a package must be designed to achieve low stray inductance for both the module and the system-level busbar design. The XM3 module beats the inductance of competitive legacy packages using a low-inductance, overlapping planar structure.

The current loops within the module are wide, low profile, and yield even distribution between the devices, resulting in equivalent impedances across a switch position. The power terminals on the module are also vertically offset. This enables design of simple bussing between the DC link capacitors and the module, laminated all the way up to the module without requiring bends, coining, standoffs or any complex isolation. The end result is a power loop stray inductance of just 6.7 nH at 10 MHz — as demonstrated in the XM3 inverter reference design.

With half the weight and volume of a standard 62 mm module, the XM3 power module maximizes power density while minimizing loop inductance and enabling simple power bussing. The XM3’s SiC-optimized packaging enables 175 °C continuous junction operation, with a high reliability Silicon Nitride (Si3N4) power substrate to ensure mechanical robustness under extreme conditions. The XM3 is a perfect fit for demanding applications such as electric vehicle chargers, UPS, and traction drives.

Select the Right XM3 for Your System Requirements

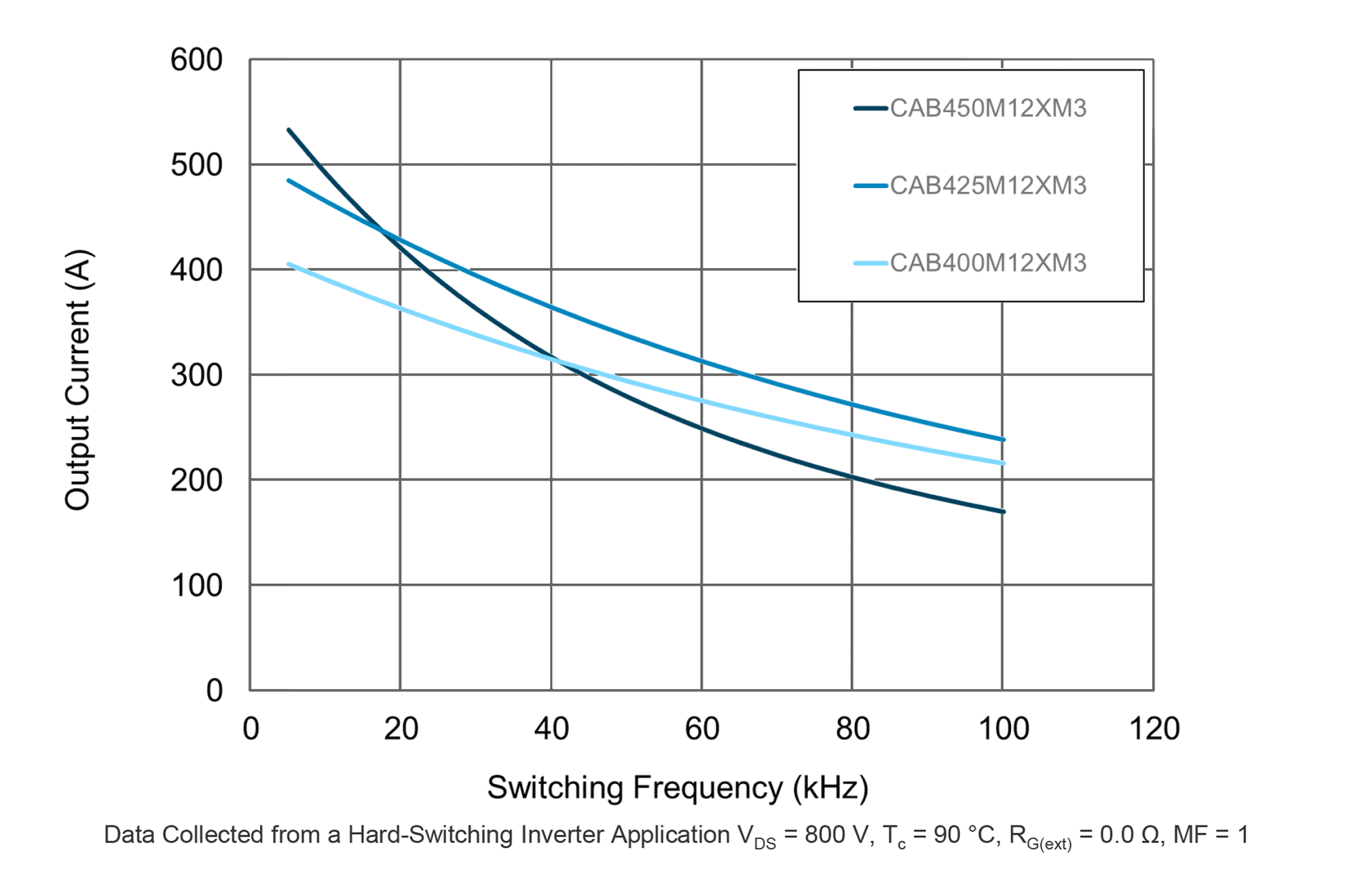

Using the XM3 Inverter Reference Design, Wolfspeed created a graph demonstrating the system-specific trade-offs between each of the XM3 device configurations. While the exact performance will be determined by the design choices within your system, this graph can be used to understand which module may fit your end-system best.

Each of the three part numbers within the XM3 module family offers tailored SiC performance that can help you achieve your system performance goals:

Part Number | Optimization | On-Resistance (TC = 25°C) | Maximum DC Current (TC = 90°C) | Switching Loss at Rated Current |

|---|---|---|---|---|

Conduction-Loss | 2.6 mΩ | 409 A | 21.1 mJ | |

Switching-Loss | 3.2 mΩ | 358 A | 8.4 mJ | |

Switching-Loss | 4.0 mΩ | 288 A | 6.9 mJ |

Ready to evaluate the performance of the XM3 power module in your application? You can start with our SpeedFit Design Simulator to input information about your system topology and operating conditions to simulate the XM3's performance in your system.

For more information or questions about the XM3 platform and supporting designs, please contact Wolfspeed.