EV Powertrain

Wolfspeed’s Silicon Carbide power components offer the industry’s lowest drain-source on resistance, which increases the distance consumers can drive on a single charge.

Wolfspeed: Designed to Support High-Voltage EV Powertrain Systems

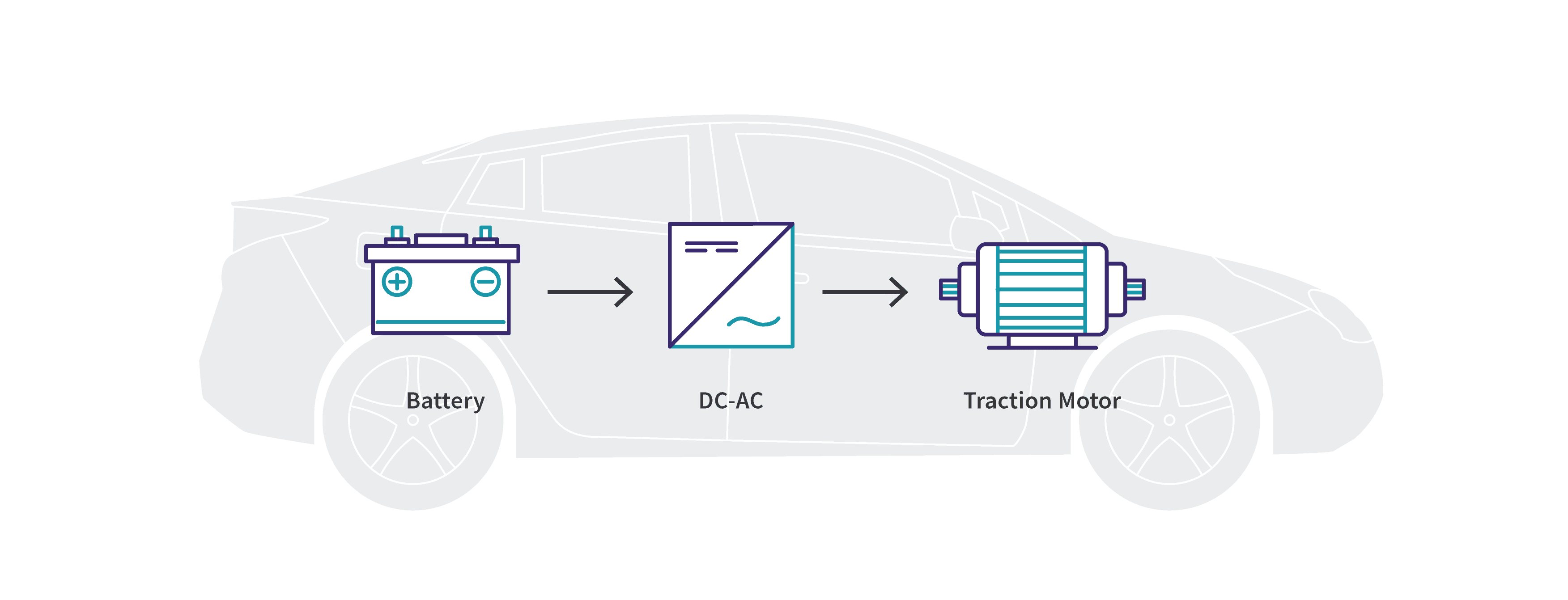

Electric vehicles (EVs) are full of advanced electrical designs — from the on-board charging system to infotainment and navigation platforms — so providing clean, efficient power is essential. But the biggest and most mission-critical system, responsible for getting the vehicle from Point A to Point B, is the EV powertrain.

Powertrains: The Heart of the Electric Vehicle

An EV’s powertrain is responsible for taking energy stored in the vehicle’s battery system and supplying it to the motors. The amount of power that it takes to move a fully loaded vehicle is enormous, and delivery needs to be instantaneous and predictable. Furthermore, the vehicle's range is most dictated by the ability to provide power with maximum efficiency and minimum resistance. The efficiency of this technology can be the difference between safely making it to your destination and getting stranded roadside.

Wolfspeed Silicon Carbide: Ready for the Future of EV Powertrains

Wolfspeed believes that Silicon Carbide (SiC) is the material best suited for the challenges of EV systems and powertrains, which is why we are committed to increasing our Silicon carbide capacity by thirtyfold by the year 2024. Wolfspeed has more than 30 years in Silicon Carbide design and manufacturing experience and stands alone as the global leader in Silicon Carbide technology.

Components Built for the EV Powertrain Challenge

When it comes to increasing efficiency and reducing power losses, Wolfspeed Silicon Carbide (SiC) stands alone — and for EV powertrain system designs, maximizing performance is key.

Wolfspeed EV Products Built to Support EV Powertrain Designs

Wolfspeed products represent the culmination of years of experience and expertise, where quality meets innovation to help bring your design forward. Wolfspeed’s 1200V and 650V Silicon Carbide MOSFETs offer the industry’s lowest drain-to-source on-resistances, enabling a reduction of EV drivetrain losses by up to 80%, which means increased range and performance for your EV.

Featured Discrete Silicon Carbide MOSFETs for EV Powertrain

Filter By

Product SKU | Buy Online | Request Sample | Data Sheet | CAD Model | Status | Blocking Voltage | RDS(ON) at 25°C | Current Rating | Tjmax | Package | Technology | Qualification |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Active | 650 V | 15 mΩ | 120 A | 175 °C | TO-247-4 | C3M | Industrial | |||||

Active | 650 V | 15 mΩ | 120 A | 175 °C | TO-247-3 | C3M | Industrial | |||||

Active | 1200 V | 16 mΩ | 115 A | 175 °C | TO-247-4 | C3M | Industrial | |||||

Obsolete | 1200 V | 16 mΩ | 115 A | 175 °C | TO-247-3 | C3M | Industrial | |||||

Active | 1200 V | 21 mΩ | 81 A | 175 °C | TO-247-3 | C3M | Industrial | |||||

Active | 1200 V | 21 mΩ | 100 A | 175 °C | TO-247-4 | C3M | Industrial | |||||

Active | 1200 V | 75 mΩ | 32 A | 175 °C | TO-247-4 | E3M | Automotive | |||||

Active | 1200 V | 75 mΩ | 32 A | 175 °C | TO-247-3 | E3M | Automotive |

Optimize with Wolfspeed to Ensure the Right Fit for Every Package

When it comes to electric vehicles, the focus of Wolfspeed bare die is reliability and best-in-class performance. Every die goes through rigid testing and evaluation to ensure long lasting products for every EV powertrain. Wolfspeed bare die symbolizes efficiency, offering multiple layouts and metal interfaces to target every power management and thermal need.

Featured Bare Die Silicon Carbide MOSFETs for EV Powertrain

Product SKU | Buy Online | Data Sheet | Status | Blocking Voltage | RDS(ON) at 25°C | Current Rating | Output Capacitance | Reverse Recovery Charge (Qrr) | Reverse Recovery Time (Trr) | Tjmax | Generation | Qualification |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Active | 1200 V | 17 mΩ | 134 A | 220 pF | 1100 nC | 52 ns | 175 °C | Gen 3 | Automotive | |||

Active | 1200 V | 17 mΩ | 134 A | 221 pF | 1242 nC | 53 ns | 175 °C | Gen 3 | Automotive |

Reference Designs to Accelerate Your Time to Market

Wolfspeed not only offers the solutions to bring your design into the future of automotive technology, but our Reference Designs can help you accelerate your design cycle process. Reference Designs include full system design resource package with schematics, BOM, and more.

Featured Reference Designs for EV Powertrains

Filter By

Product SKU | Name | Buy Online | Type | Topology | Power | Discrete/Module | Package | Device SKU(s) | Designed By | View Product |

|---|---|---|---|---|---|---|---|---|---|---|

DC to AC | Three-Phase 2-Level | 200kW | Module | XM | Wolfspeed | |||||

DC to AC | Three-Phase 2-Level | 250kW | Module | XM | Wolfspeed | |||||

DC to AC | Three-Phase 2-Level | 300kW | Module | XM | Wolfspeed | |||||

DC to AC | Dual Three-Phase, Three-Phase 2-Level | 600kW | Module | XM | Wolfspeed |