650 V Silicon Carbide MOSFETs Extend Wolfspeed’s AEC-Q101 Qualified E3M Range

Article

The rapid growth expected in the electric vehicle (EV) market — expected to be as much as 25% CAGR over the next decade1 — is driven by environmental concerns and government support and enabled by Silicon Carbide (SiC) device technology that addresses the requirements of high efficiency and power density.

The on-board charger (OBC) is one of the key power electronics systems in modern EVs and comprises AC-DC and DC-DC power stages. In today's mainstream models, 6.6 kW unidirectional OBCs are popular in EVs with 400 V battery systems. However, there is a growing trend toward bidirectional OBCs to support emerging vehicle-to-grid (V2G) services.2

Wolfspeed's new automotive qualified E-Series (E3M) 650 V, 60 mΩ MOSFET family helps designers meet the demands of the EV OBC application space. Developed using the company's 3rd generation SiC MOSFET technology, the E3M0060065D and E3M0060065K devices (Figure 1) feature high blocking voltage with low ON-resistance, high-speed switching with low capacitances, a very low reverse recovery charge (Qrr) due to a fast body diode, as well as a high maximum junction temperature, Tj, of 175° C.

Importantly, the devices are fully automotive qualified to the AEC-Q101 (Rev. E) standard and are Production Part Approval Process (PPAP) capable. The PPAP feature implies that all specification requirements of designers are well understood and consistently achieved by Wolfspeed, giving designers full confidence in the device production process.

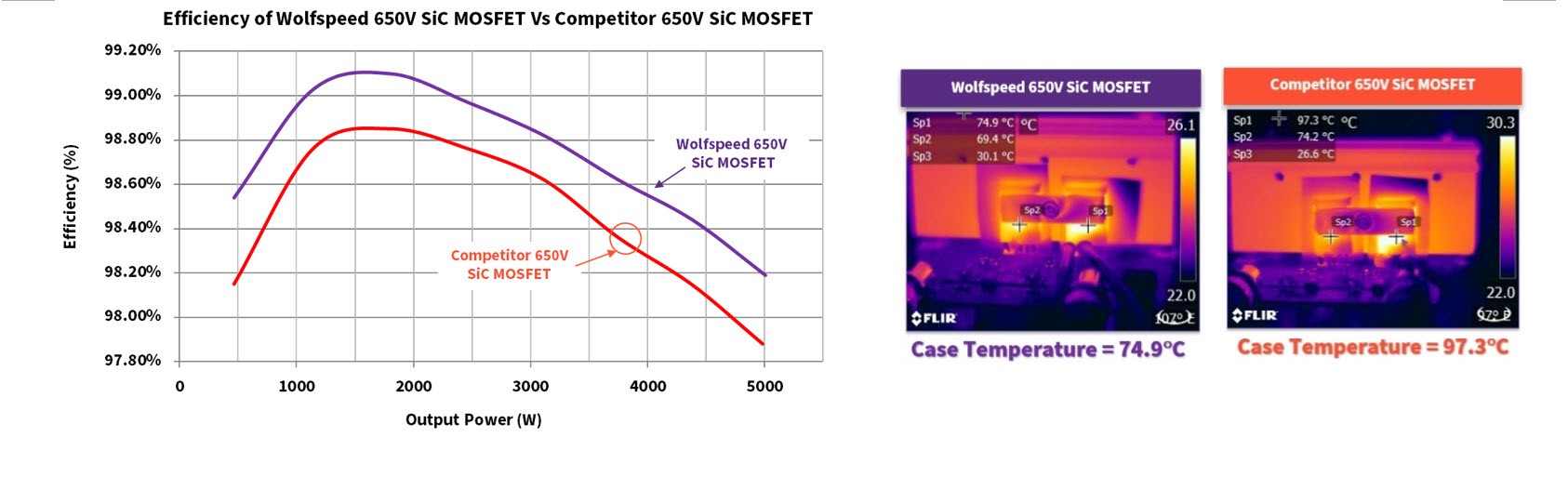

In comparison to the 650 V Silicon Carbide MOSFETs available in the market, Wolfspeed’s E3M 650 V Silicon Carbide MOSFET technology enables systems to run cooler due to lower losses — delivering significantly higher efficiencies (Figure 2) in end applications. The lower losses translate to a reduced case temperature, which lowers system-level thermal management and enhances system-level power density.

Choosing the package for your design

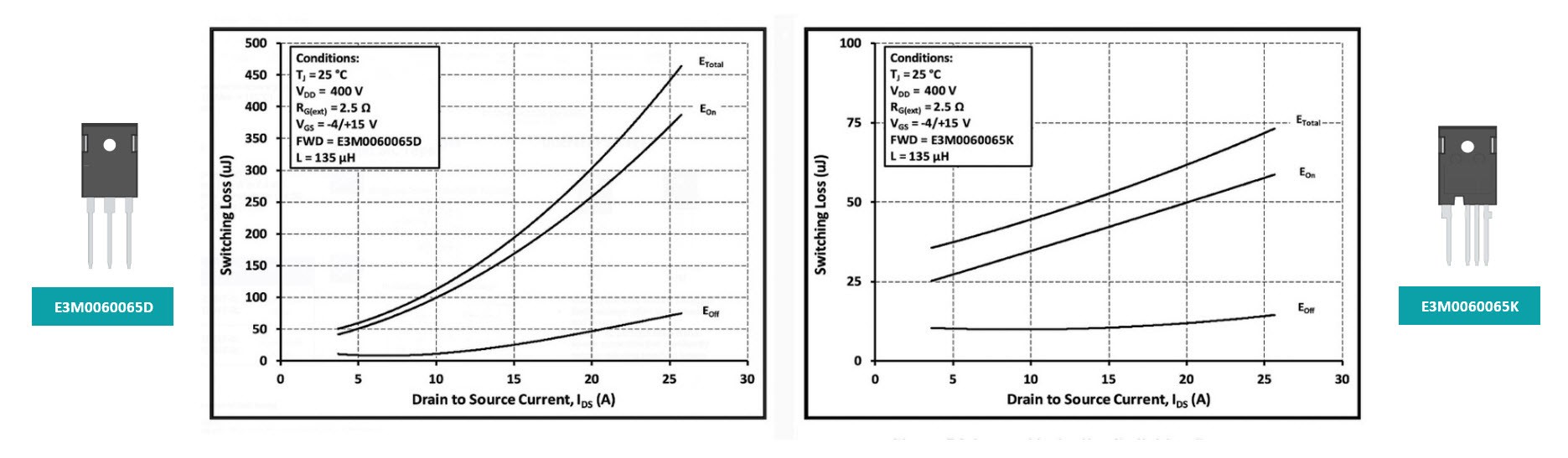

Wolfspeed’s new E-Series 650 V 60 mΩ SiC MOSFETs come in two different package types. The E3M0060065D comes in a three-lead TO-247-3L package, whereas E3M0060065K is available in a four-lead version — the TO-247-4L — accommodates a Kelvin source pin. The Kelvin source connection eliminates the source inductance — enabling lower switching losses and faster switching speed.

The Kelvin source allows designers to utilize the best of the switching characteristics that Silicon Carbide devices have to offer. The same die in different packages can thus offer different performance. For instance, the total switching loss, ETOTAL, of the E3M0060065D at an IDS of 20 A is about 300μJ whereas for the E3M0060065K, the ETOTAL under the same conditions is close to 62μJ (Figure 3).

E-Series (E3M) 650 V 60 mΩ Silicon Carbide MOSFET in EV OBC Application

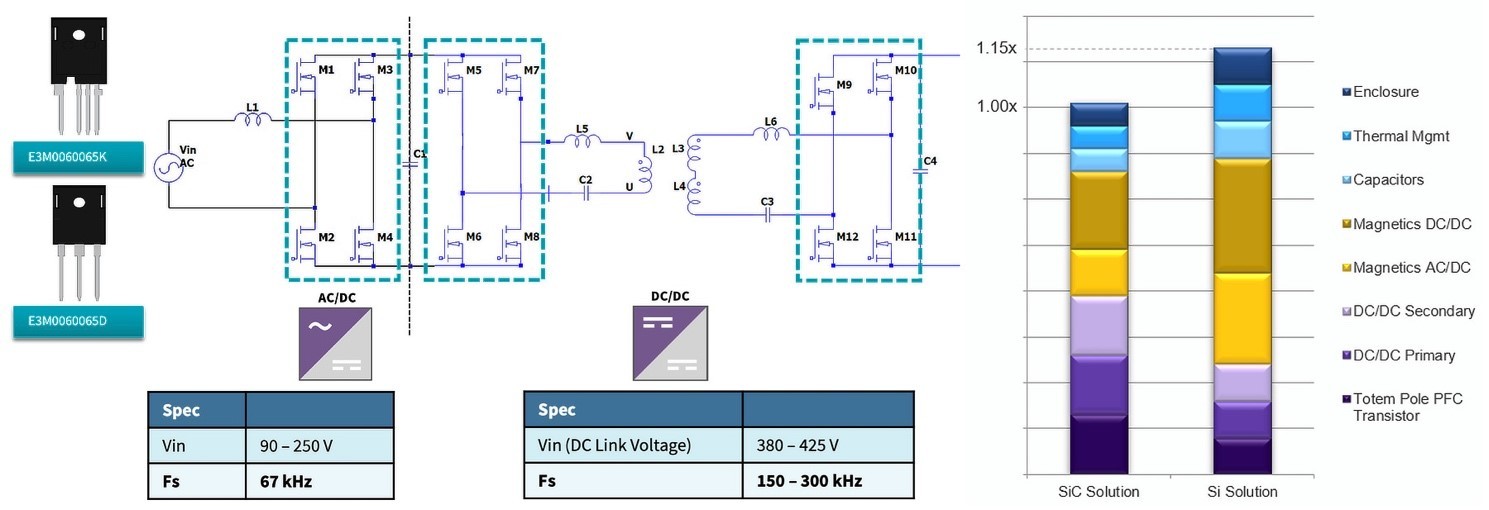

A typical Silicon Carbide MOSFET-based bidirectional design, shown in Figure 4, comprises a totem pole configuration for the AC-DC section and a bidirectional CLLC resonant DC-DC, all of which can benefit from the new E-Series (E3M) 650V SiC MOSFETs.

Compared with an all-Silicon bidirectional EV OBC design, Wolfspeed E-Series (E3M) 650 V 60 mΩ SiC MOSFET design enables significant savings in passives, including capacitors and magnetics, as well as thermal management and enclosure costs. These savings are enabled primarily by the ability to increase switching frequency, Fs, while achieving higher efficiency. For instance, the AC-DC section switches at 67 kHz against Silicon’s typical high point at 20 kHz. Similarly, the DC-DC switching frequency can be increased from Silicon’s typical 80-120 kHz range to Silicon Carbide-based solution’s 150-300 kHz.

Get Wolfspeed’s Design-in Help

Wolfspeed offers several reference designs and evaluation kits to ease design pains. The 6.6 kW bidirectional OBC reference design, CRD-06600FF065N-K, gets projects started quickly and helps design-in the new E3M 650 V SiC MOFETs.

More information on the E3M0060065D and E3M0060065K is available at the E-Series page featuring Wolfspeed’s family of automotive qualified, PPAP-capable, and humidity-resistant MOSFETs with the industry’s lowest switching losses and highest figure of merit.

References

- IDTechEx, Power Electronics for Electric Vehicles 2022-2032, (https://www.idtechex.com/)

- Sai Sudharshan Ravi, et al., January 2022, Utilization of Electric Vehicles for Vehicle-to-Grid Services: Progress and Perspectives (https://mdpi-res.com/d_attachment/energies/energies-15-00589/article_deploy/energies-15-00589.pdf)