Electric Commercial, Construction & Agriculture Vehicles

Innovative and flexible semiconductor solutions for e-mobility on land

From small utility vehicles to larger, more complex machinery, many types of commercial, construction, and agriculture vehicles (CAVs) have started to transition from internal combustion engine (ICE) and diesel power to electric powertrains.

On and off the highway, battery electric (BEV) and fuel cell electric (FCEV) CAVs are powered by electricity sourced from batteries, hydrogen fuel, or overhead power lines. BEVs and FCEVs operate similarly to their traditional counterparts but with the added benefits of electric power such as reduced emissions, quieter operation, fewer system-level passive components, lower maintenance, and lower total cost of ownership.

Electric CAVs

In order to achieve best-in-class performance under demanding environmental conditions, including harsh climates, continuous vibration, and exceptional loads, electric CAVs rely on the latest semiconductor solutions to deliver maximum power density, robust thermal cycling capability, higher peak performance, greater efficiency, and higher reliability and quality over a long lifetime.

Commercial

Electric semi-trucks and transit buses transport people and good over long distances. These vehicles will soon require an expanded charging infrastructure, up to the megawatt-level.

Construction

Electric forklifts, excavators, loaders, and mining trucks gather and transport materials on work sites, inside warehouses and facilities, at shipyards, and more. These vehicles navigate continuous vibration and exceptional loads and therefore rely on high-quality semiconductors to maintain peak performance over a long lifetime.

Agriculture

Electric tractors, foragers, harvesters, and sprayers cultivate and harvest crops as well as raise and support livestock. These vehicles face harsh climates and depend on reliable semiconductor solutions to deliver robust thermal cycling capability, greater efficiency, and higher quality.

Applications

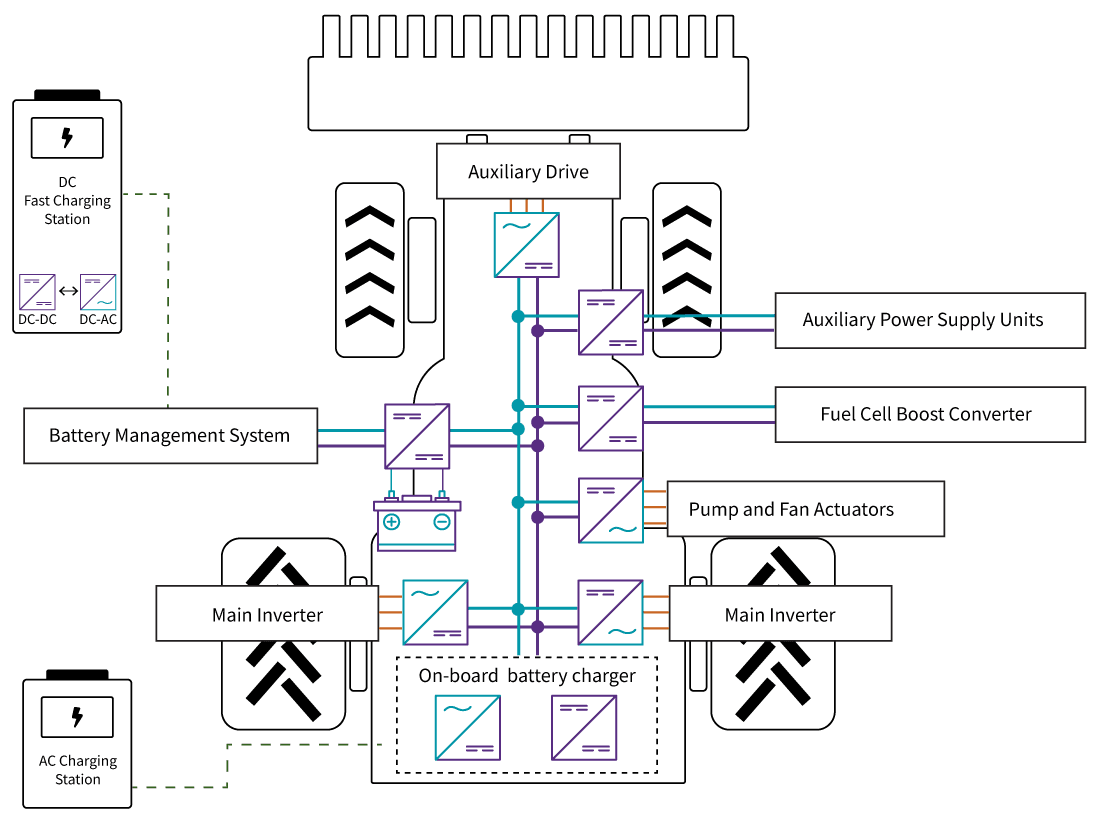

Wolfspeed silicon carbide power semiconductors are suited to the unique requirements of each power electronic system integrated throughout electric CAVs.

Click on the interactive block diagram to view common topologies (and suggested products) for each power system.

Products

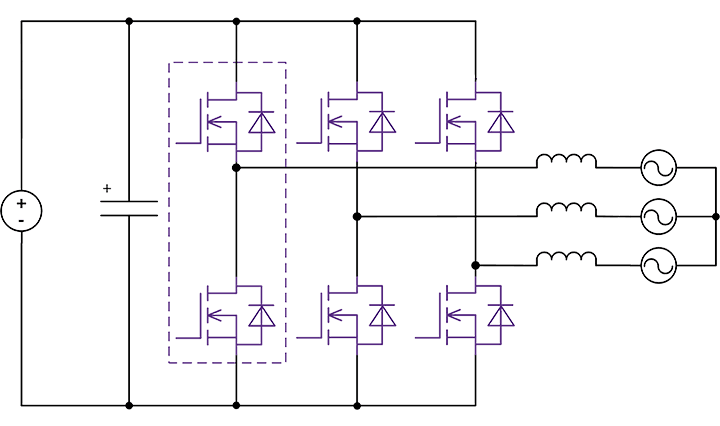

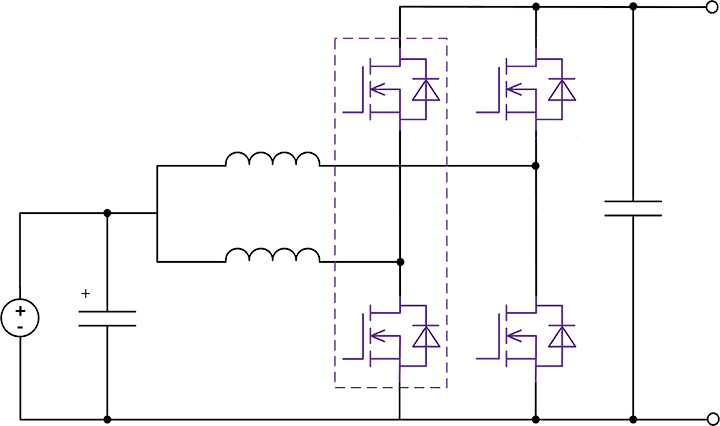

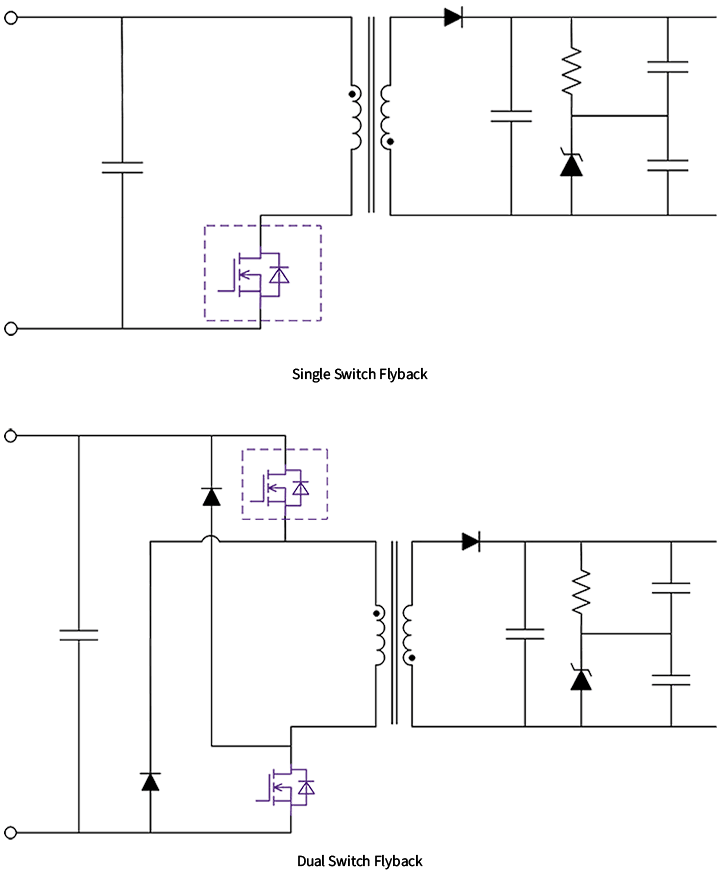

Click on the interactive topology diagrams to select the right products for your system design.

Featured Reference Designs

Filter By

Product SKU | Name | Buy Online | Type | Topology | Power | Discrete/Module | Package | Device SKU(s) | Designed By | View Product |

|---|---|---|---|---|---|---|---|---|---|---|

DC to DC | Flyback | 0.015kW | Discrete | TO-263-7 | Wolfspeed | |||||

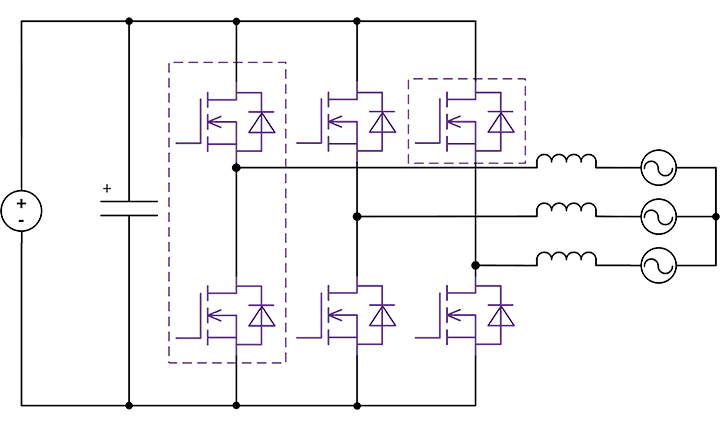

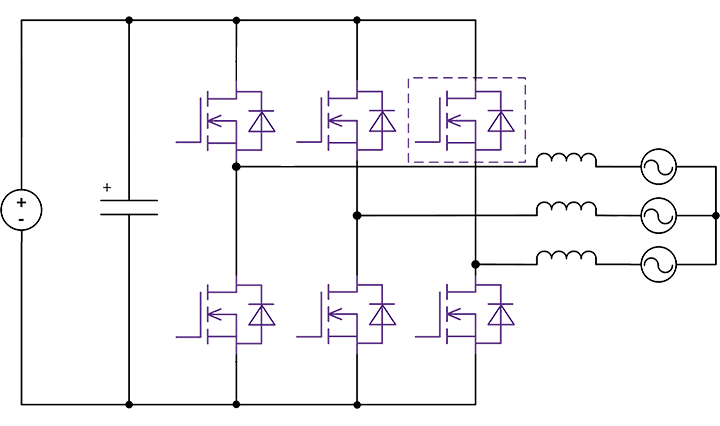

AC to DC, DC to AC | Passive Rectifier and Three-Phase, Three-Phase 2-Level | 7.5kW | Module | FM | Wolfspeed | |||||

AC to DC | Three-Phase 2-Level | 22kW | Discrete | TO-247-4 | Wolfspeed | |||||

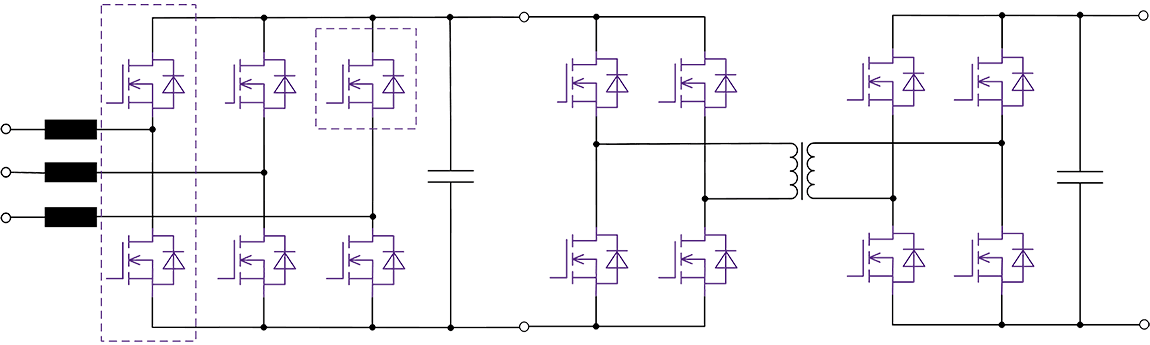

DC to DC | CLLC | 22kW | Discrete | TO-247-4 | Wolfspeed | |||||

DC to AC | Three-Phase 2-Level | 25kW | Module | FM | Wolfspeed | |||||

DC to DC | LLC (3 Phase) | 30kW | Discrete | TO-247-4, TO-220-2, TO-247-3 | Wolfspeed | |||||

DC to AC | Three-Phase 2-Level | 200kW | Module | XM | Wolfspeed | |||||

DC to AC | Three-Phase 2-Level | 250kW | Module | XM | Wolfspeed | |||||

DC to AC | Three-Phase 2-Level | 300kW | Module | XM | Wolfspeed | |||||

DC to AC | Dual Three-Phase, Three-Phase 2-Level | 600kW | Module | XM | Wolfspeed |